Introduction

Manual for installing the LGX - Mosquito extruder on a 10mm Caribou. This manual covers the FDM as well as the SLS printed parts.

-

-

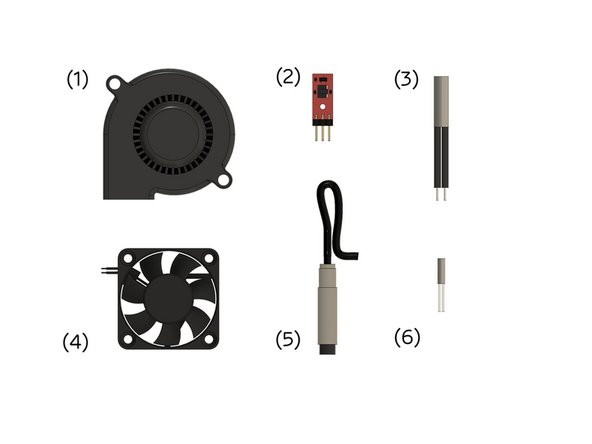

(1) Radial fan

-

-

(3) Heater

-

(4) Sunon fan

-

(5) PINDA2 / SuperPINDA

-

(6) Thermistor

-

(7) Nylonfilament (not in the picture)

-

Caribou 220: 47cm Caribou 320: 57cm Caribou 420: 67cm

-

-

-

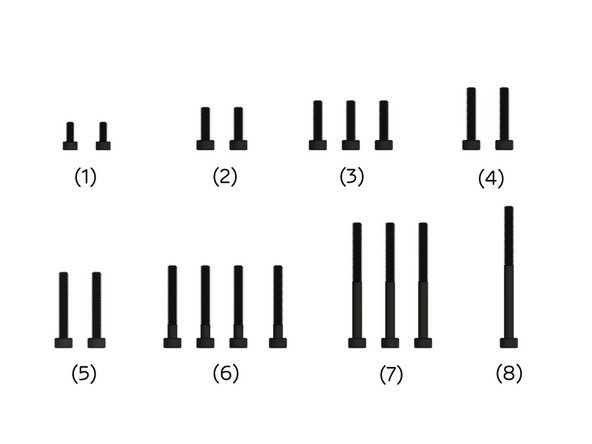

(1) 2x M2.5x6mm head cap screws (supplied with Mosquito hot end)

-

-

-

-

-

-

-

-

-

-

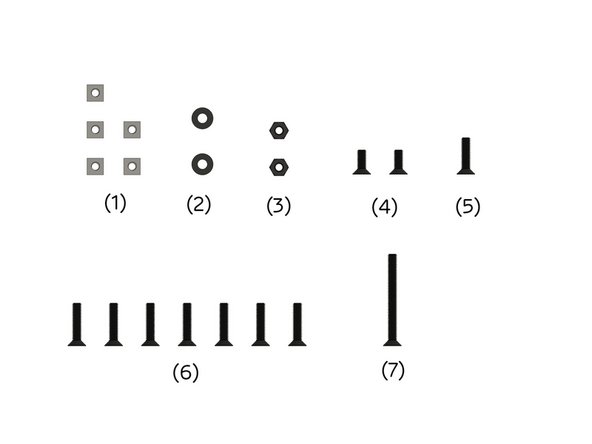

(1) 5x M3 square nuts

-

(2) 2x M3 washers

-

(3) 2x M3 nuts

-

-

-

-

(7) M3x30mm hex drive flat head screw

-

-

-

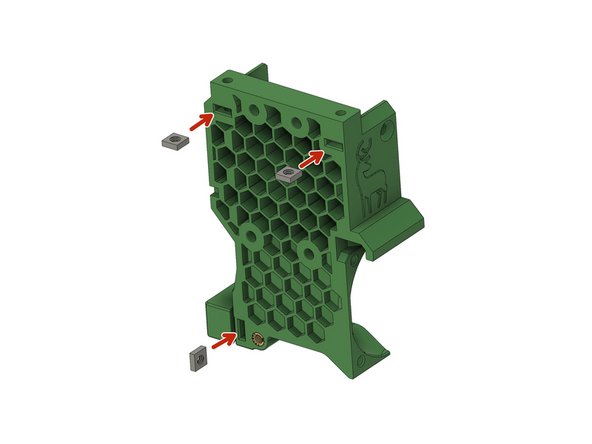

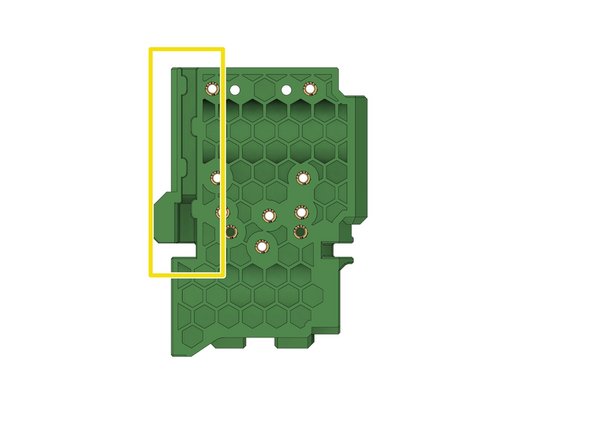

Insert 3x M3 square nuts into the back of the LGX holder.

-

Insert 2x M3 square nuts into the botton of the x-carriage.

-

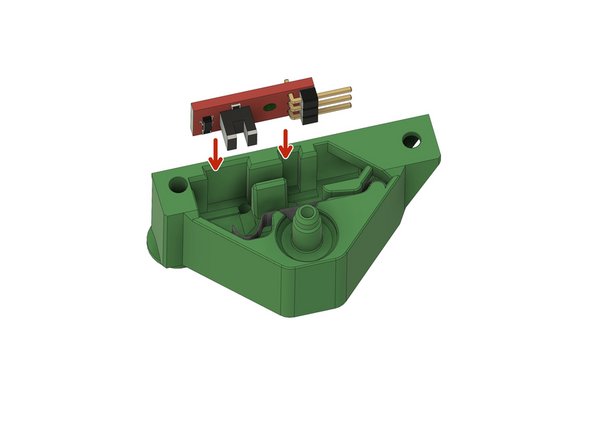

Route the cable of the filament sensor through this channel. Let the cable stand out about 4cm at the top.

-

Make sure the cable has the correct orientation. The 3-pin connector goes to the sensor, the 5 pin connector goes to the board.

-

-

-

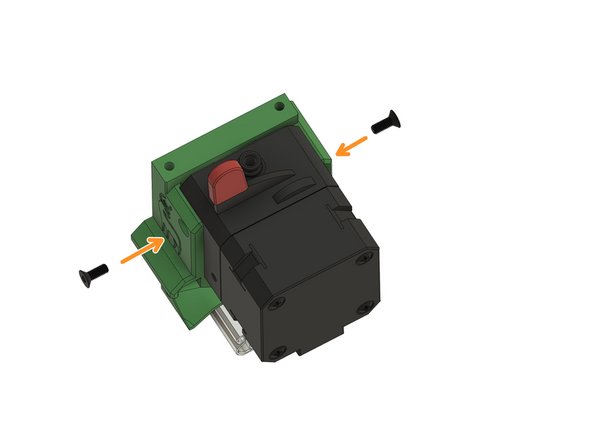

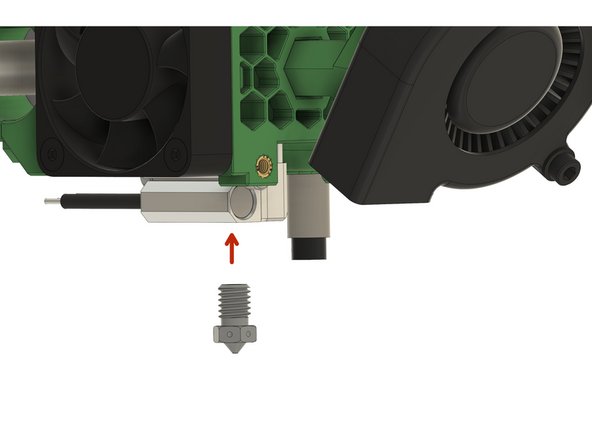

Slide the hotend into the LGX holder.

-

Use 2x M2.5x6mm head cap screw to secure the hotend in place.

-

Cut the PTFE tube to 19.7mm length using the provided cutting tool.

-

Slide the PTFE tube into the middle hole. Make sure to insert the tube all the way into the top of the Mosquito.

-

Make sure the chamfered side of the tube shows to the top.

-

-

-

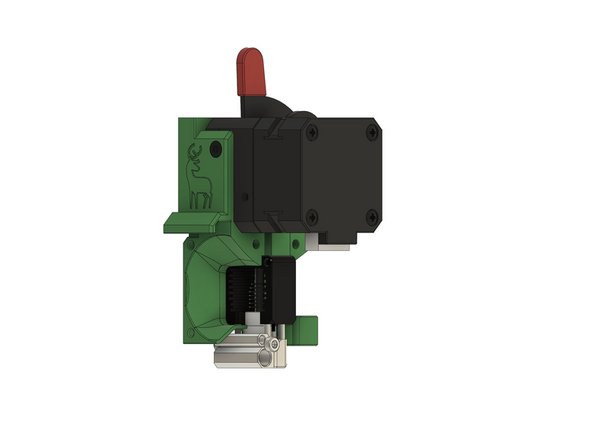

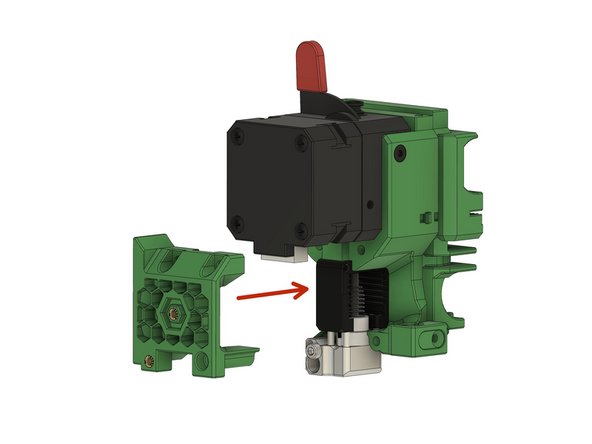

Carefully slide the LGX extruder into place.

-

Make sure the PTFE tube slides into the hole at the bottom of the extruder.

-

Use 2x M3x6mm flat socket head cap screws to secure the extruder.

-

-

-

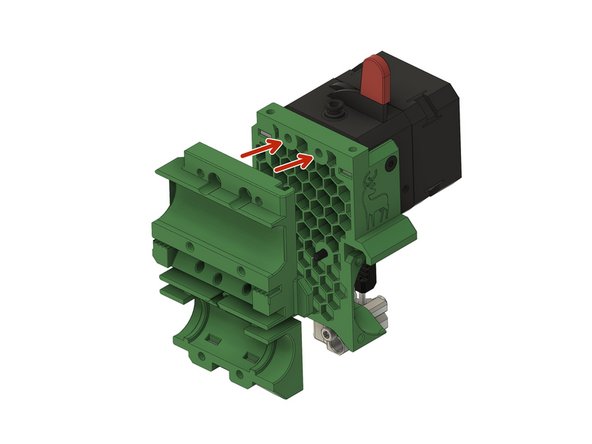

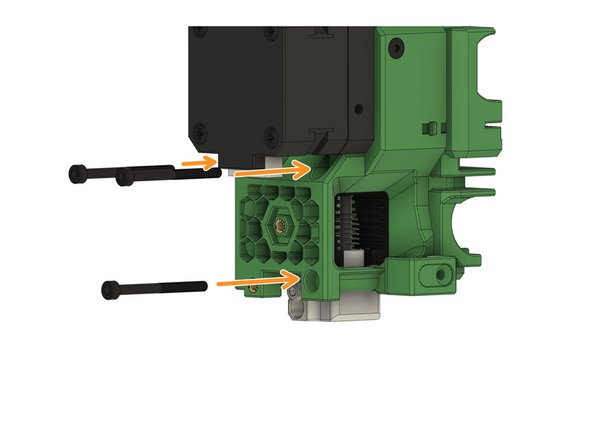

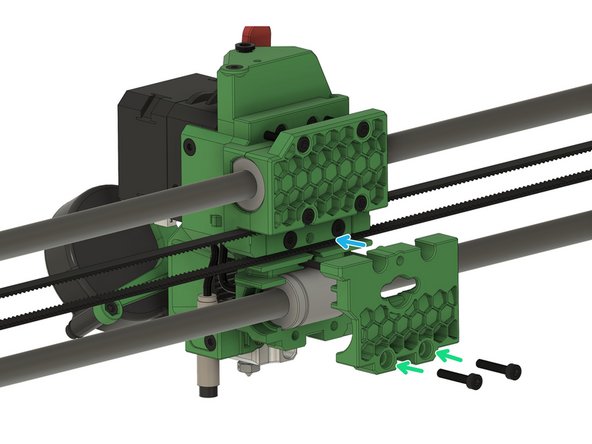

Place the back of the x-carriage against the back of the LGX holder.

-

Make sure that the cable of the filament sensor sits in the channel of the x-carriage and is not pinched between the two plastic parts.

-

Use 2x M3x12 head cap screws to screw the parts together.

-

-

-

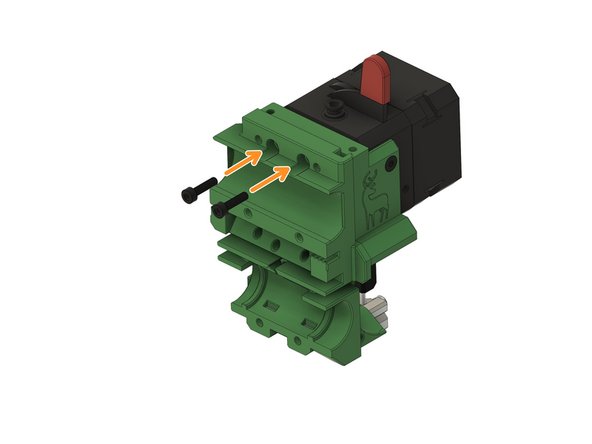

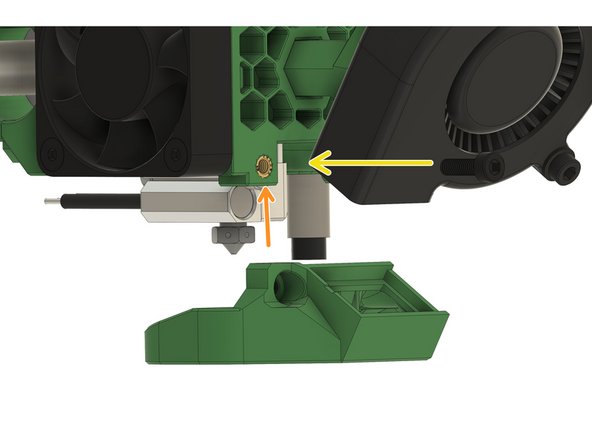

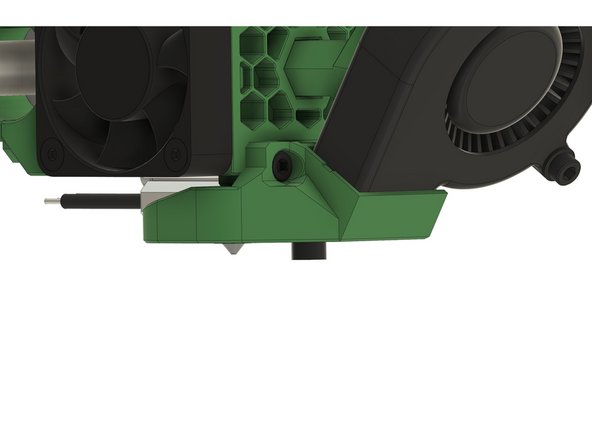

Attach the cover (as shown in picture 1) to the front of the holder.

-

Use 3x M3x35mm head cap screws to fasten the cover.

-

-

-

Connect the motor cable to the motor and route the cable through the channel.

-

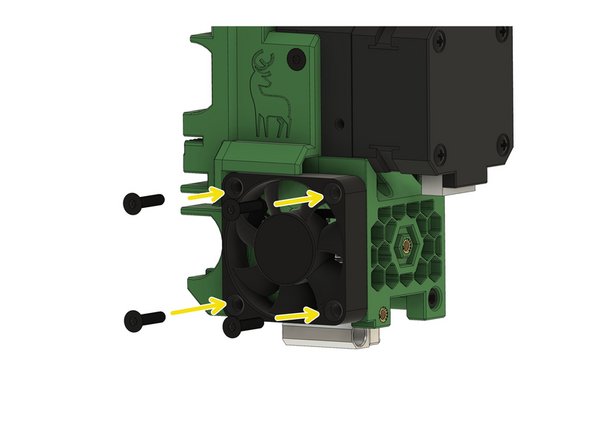

Place the extruder on the LGX holder in such a way that (1) the cables are pointing towards the channel and (2) the sticker on the fan is pointing towards the inside of the extruder.

-

Use 4x M3x16mm flat socket head cap screws to fasten the extruder fan.

-

Route fan's cable through the channel to the back of the x-carriage.

-

-

-

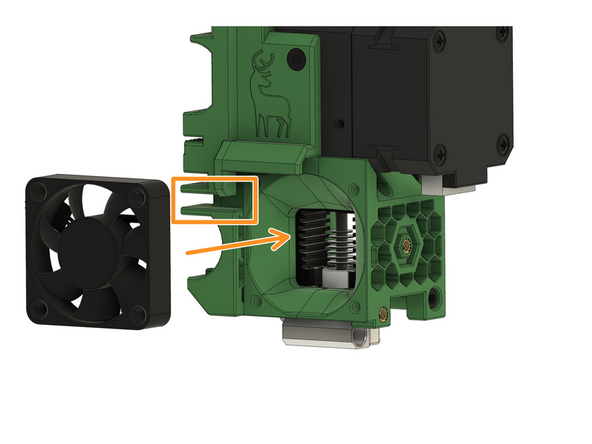

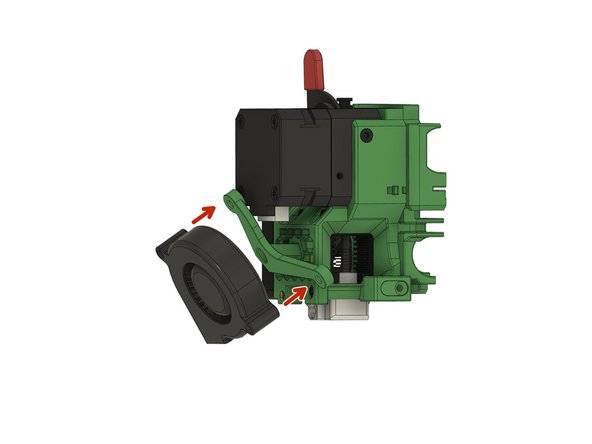

Push 2x M3 nuts into the radial fan holder.

-

Place the radial fan holder in front of the cover.

-

Use a M3x12mm head cap screw to fasten the holder.

-

-

-

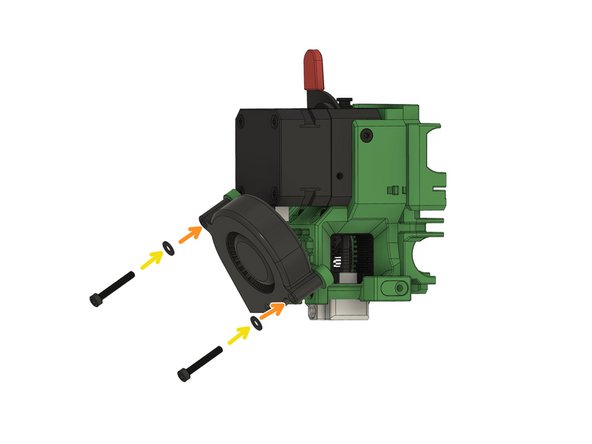

Place the screw holes of the radial fan in front of the screw holes of the radial fan holder.

-

Pay attention to the orientation of the fan.

-

Use 2x M3 washers and...

-

2x M3x20mm head cap screws to fasten the fan to the holder.

-

-

-

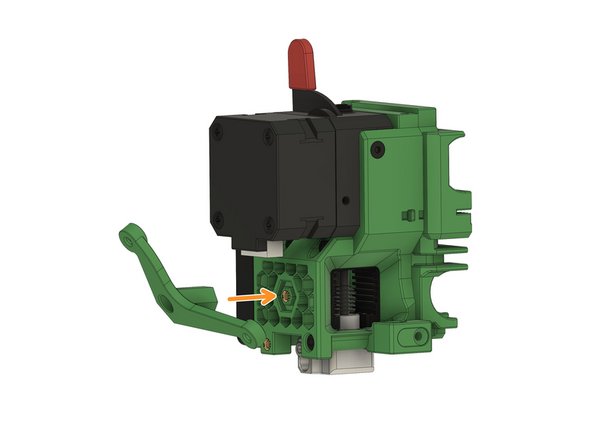

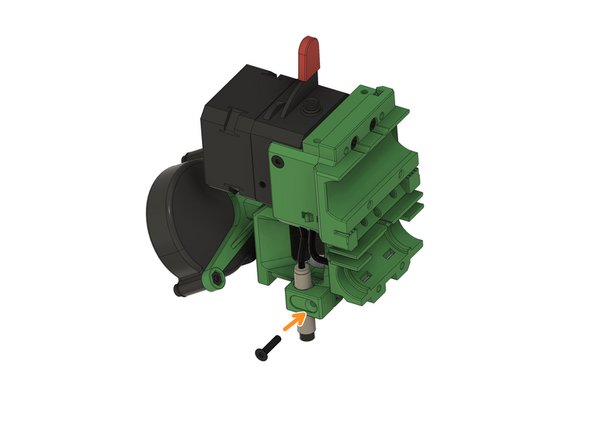

Insert the PINDA / SuperPINDA into the hole on the side of the holder.

-

Fasten the sensor with a M3x12mm flat socket head cap screw.

-

First, route the cable of the radial fan through the channel.

-

Form a loop with the sensor cable and route it through the channel.

-

Fasten the loop with a zip-tie to the LGX holder.

-

-

-

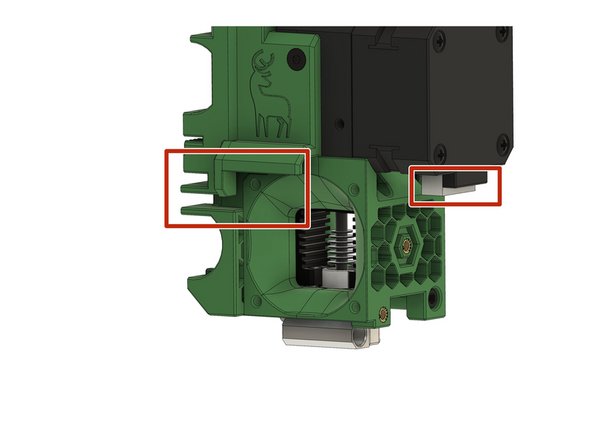

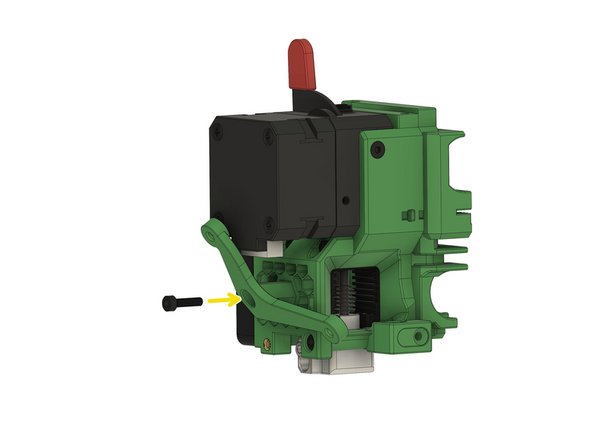

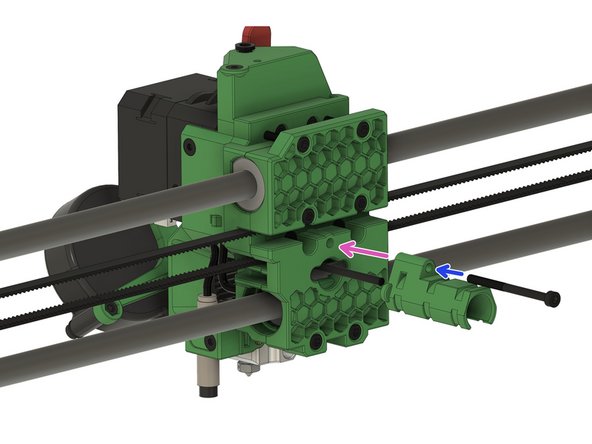

Remove the bowden coupler from the extruder.

-

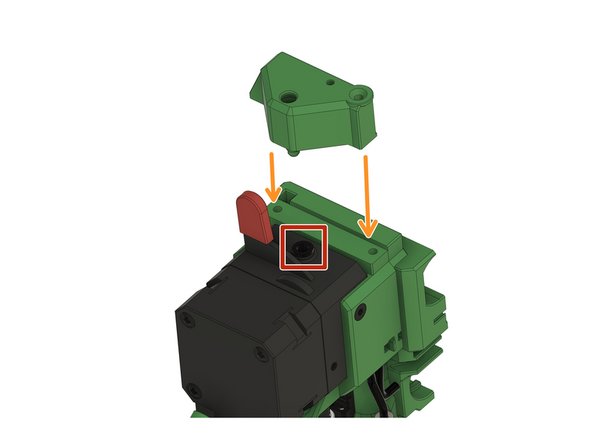

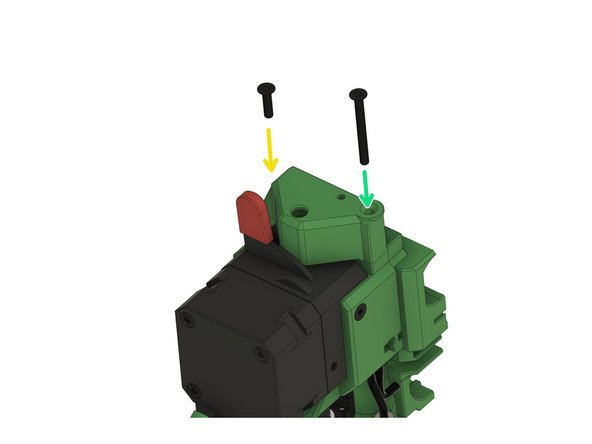

Place the sensor housing on top of the extruder.

-

Use a M3x12mm flat socket head cap screw...

-

...and a M3x30mm flat socket head cap screw to fasten the filament sensor housing.

-

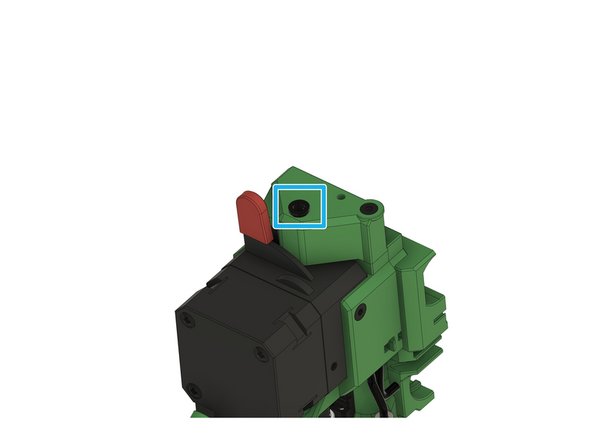

Insert the bowden coupling into the filament sensor housing.

-

Attach the cable to the sensor.

-

-

-

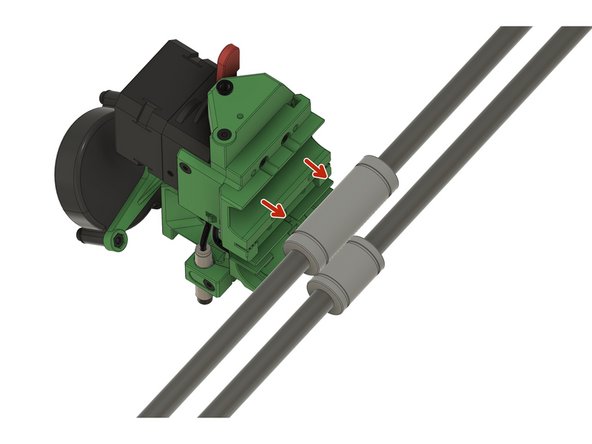

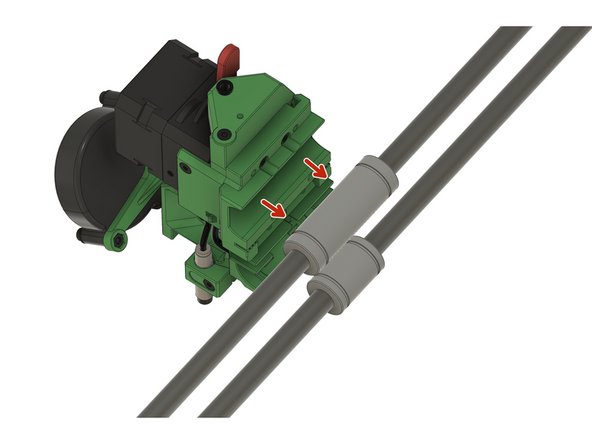

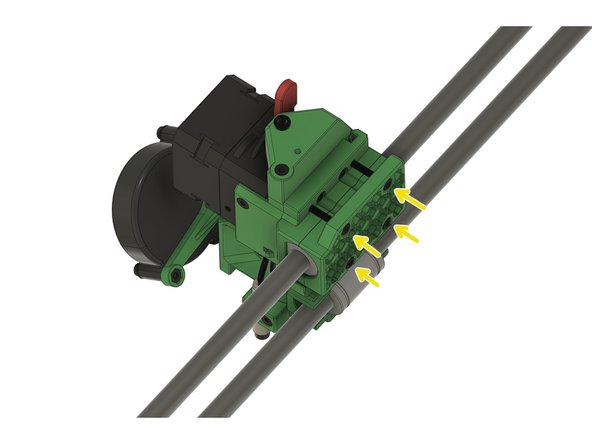

Align the bearings with the x-carriage back.

-

Bring the top holder back into position.

-

Use 4x M3x22 head cap screws to fasten the back part.

-

Do not overtighten the screws!

-

-

-

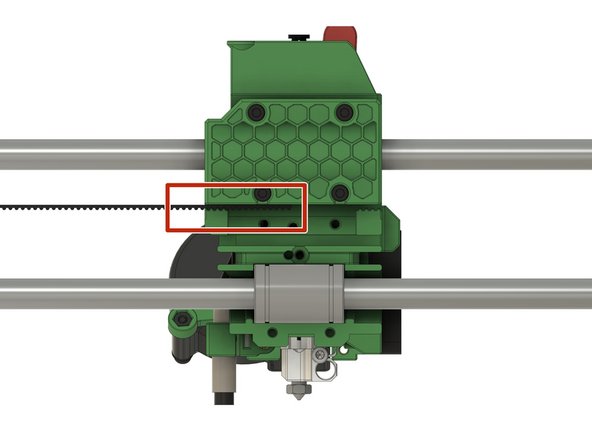

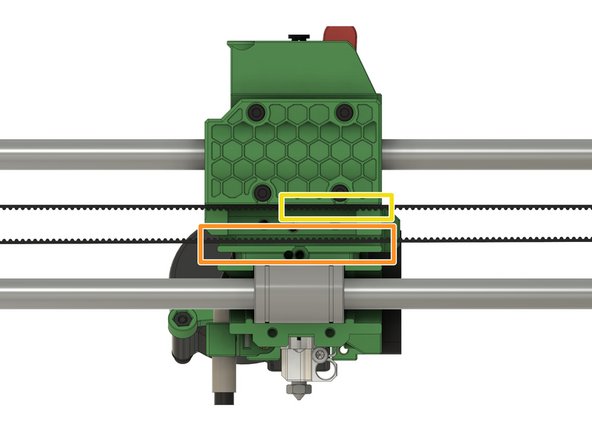

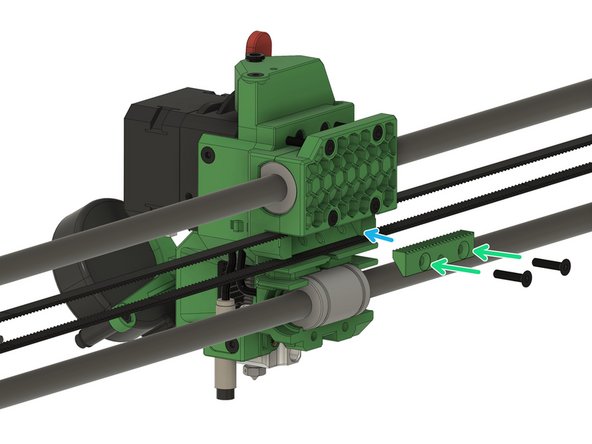

Insert one end of the belt into the x-carriage. It should be inserted half way into the x-carriage.

-

Route the belt through the x-idler and the x-motor holder (not shown here).

-

The belt must run through the lower channel of the x-carriage.

-

Cut the belt so that you can insert the other end of the belt into the x-carriage. Both belt ends should touch each other inside the x-carriage.

-

Use 2x M3x14mm flat head screws to...

-

...fasten the belt holder into the x-carriage.

-

-

-

Insert the 2.85mm nylon filament into the hole next to the screw hole.

-

Use a M3x10mm head cap screw to secure the nylon filament in position.

-

Route the cables for the fans, the PINDA, the filament sensor cable, and the extruder motor through the hole.

-

Use 2x M3x16mm head cap screws to...

-

...fasten the carriage's back bottom part to the x-carriage.

-

Use a M3x40mm head cap screw to...

-

...fasten the cable holder to the x-carriage.

-

-

-

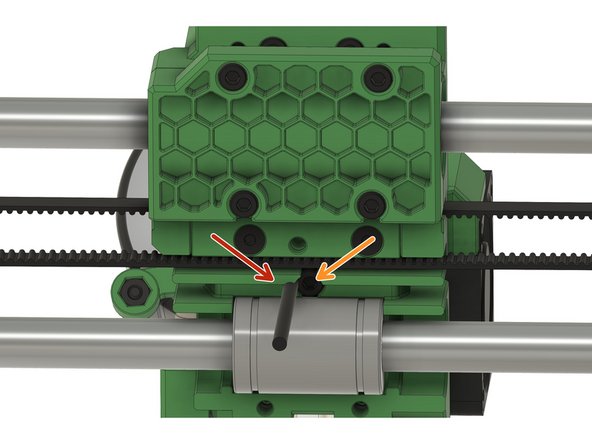

Remove the M2.5x5mm head cap screw on the back of the Mosquito.

-

Apply boron nitride paste to both the heater cartridge and the thermistor cartridge.

-

Insert the thermistor cartridge into the upper hole.

-

Insert the heater cartridge into the lower hole.

-

Fasten the M2.5x5mm head cap screw to secure the cartridges.

-