-

-

(1) 1.5x60mm Hexagon Socket Head Screwdriver for Electronic Applications

-

-

-

(4) Engineer Scriber

-

-

(6) Super Lube

-

(7) Injectors

-

(8) Isopropanol (optional)

-

-

-

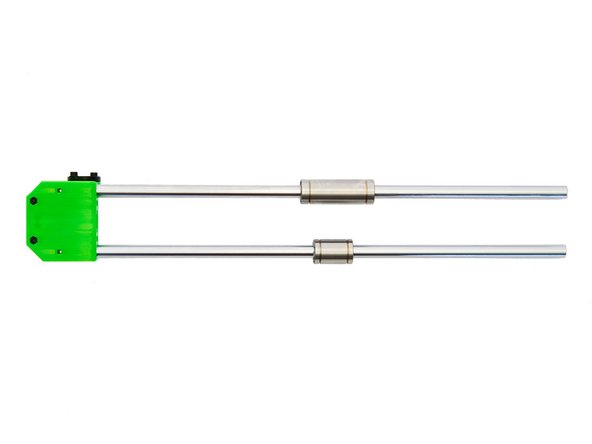

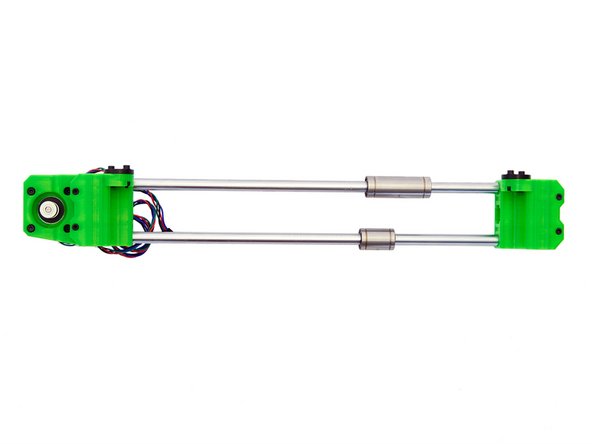

(1) 2x x-Rod 380mm

-

(2) Stepper Motor

-

(3) LMU10 Bushing

-

(4) 3x LMUW10 Bushing

-

-

(6) 2x POM Nut

-

(7) x-Motor Holder

-

(8) x-Idler

-

-

-

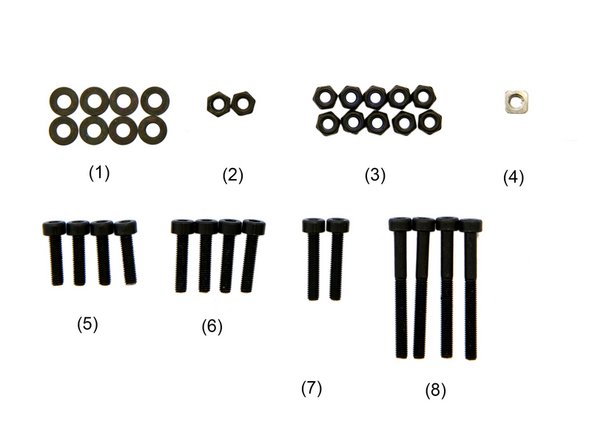

(1) 8x Black M3 Washers

-

(2) 2x M3 Nuts

-

(3) 10x M3 Self-Securing Nuts

-

(4) M3 Square Nut

-

-

-

-

-

-

-

To prepare for later, 3x LMUW10 bushings and one LMU10 bushing must be placed in isopropanol for 15min.

-

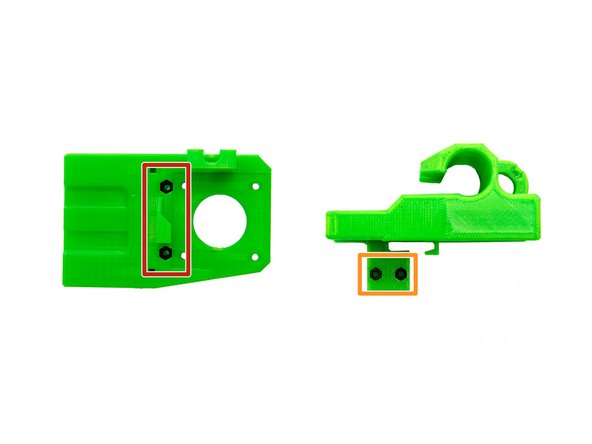

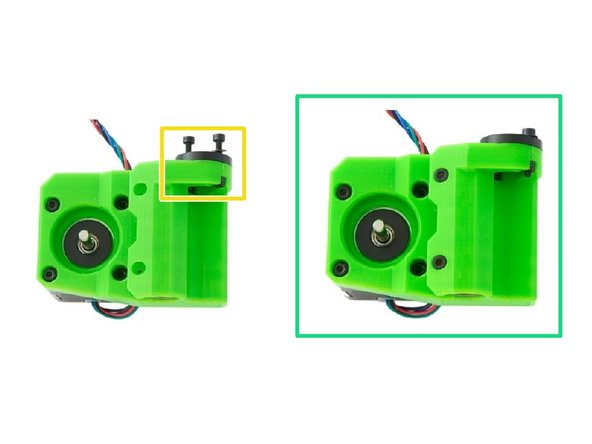

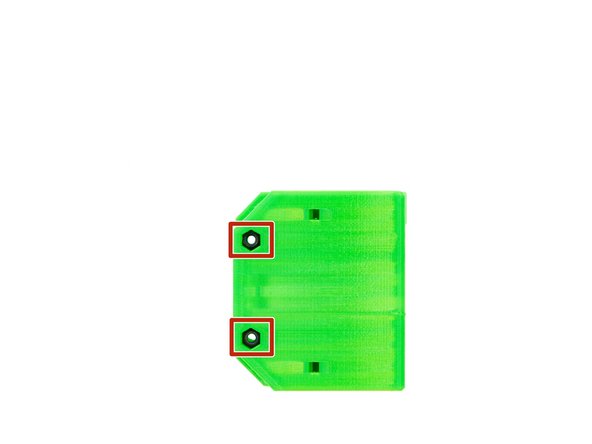

Insert 2x M3 Self-Securing Nuts into the back of the x-motor holder.

-

Insert 2x M3 Nuts into the bottom of the cable guide at the back of the x-motor holder.

-

Tighten the 2x M3 Self-Securing Nuts and the 2x M3 Nuts with a screwdriver or an engineer scriber if necessary.

-

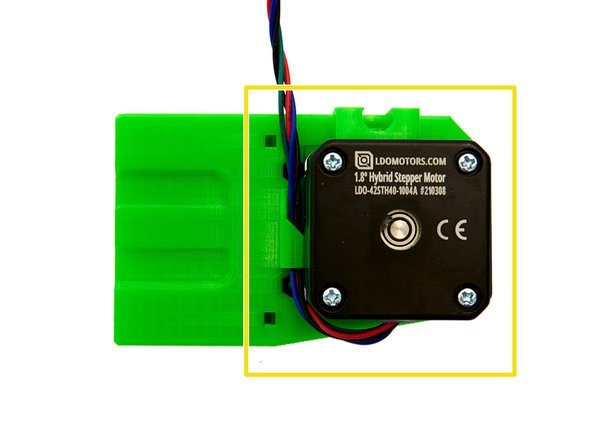

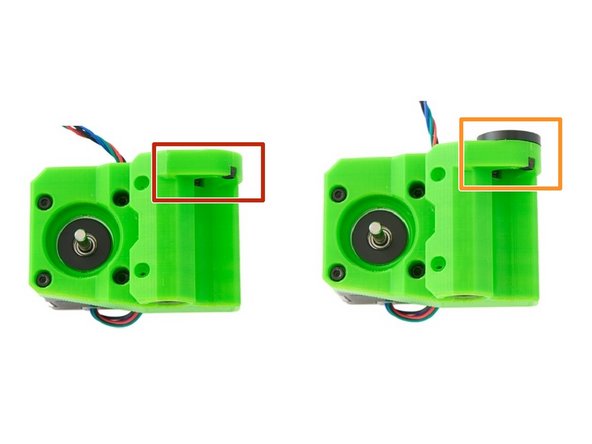

Place a stepper motor on the back of the x-motor holder. When doing so, pay close attention to the alignment (see Fig. 2).

-

Make sure that the cables are routed through the cable holder.

-

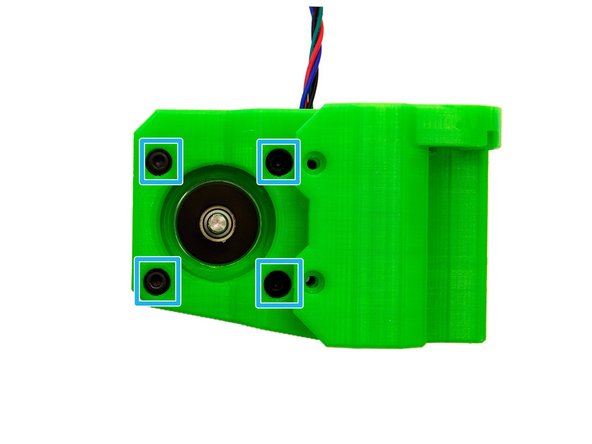

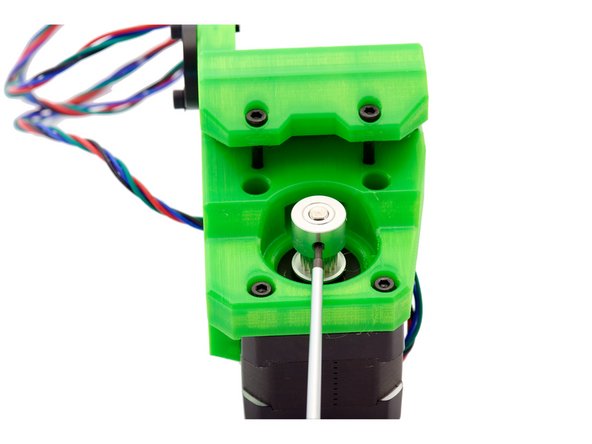

Hold on to the stepper motor and turn the x-motor holder. Place 4x M3 Washers in the four openings of the x-motor holder. Then, fasten the stepper motor to the x-motor holder with 4x M3x12mm Hexagon Socket Head Cap Screws.

-

-

-

Now, you need the bushings you have prepared in the first step. They must be dryed and then greased with Super Lube.

-

One of the greased LMUW10 bushings is pushed into the x-motor holder so that it is centered. Then the bushing is fixed with 2x M3x30mm Hexagon Socket Head Cap Screws.

-

When doing so, make sure that you only tighten the M3 Hexagon Socket Head Cap Screws minimally so that the screw is flush with the M3 Self-Securing Nuts.

-

-

-

Check the hole for the POM nut for filament protrusions and remove them with a knife or scalpel if necessary.

-

Insert 2x M3 Self-Securing Nuts into the designated slots.

-

Insertion can be made easier with the help of an engineer scriber.

-

Now place a POM nut in the hole on the top.

-

Use 2x M3 Washers and 2x M3x14mm Hexagon Socket Head Cap Screws to fix the POM nut.

-

Here, make sure that you screw the screws into the threaded holes of the POM nut.

-

Do not tighten the 2x M3x14mm Hexagon Socket Head Cap Screws completely at this stage.

-

-

-

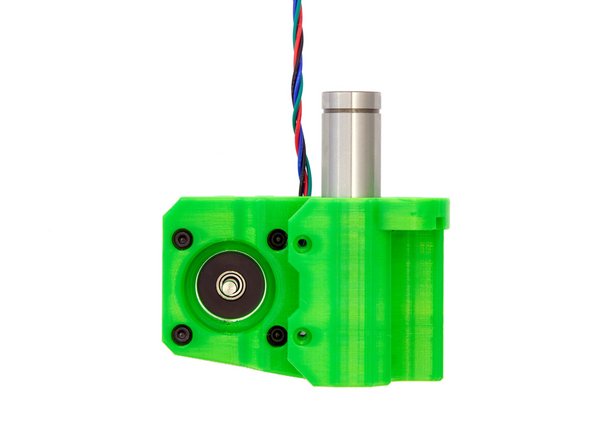

Slide the GT3 pulley onto the shaft of the stepper motor.

-

The motor shaft has two grub screws. Make sure that one of them is aligned with the flat surface of the shaft and tighten both grub screws.

-

Leave a narrow gap between the pulley and the motor surface to avoid friction.

-

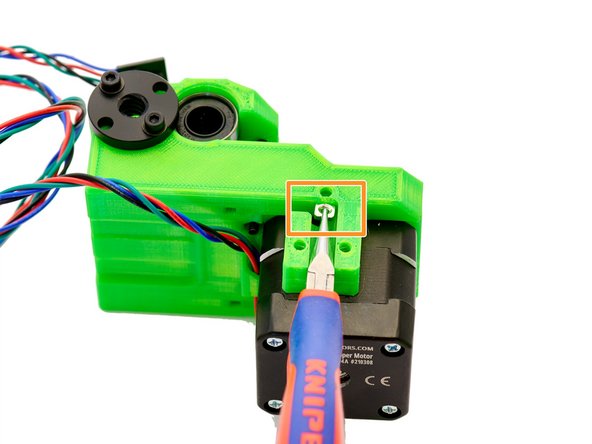

Insert a M3 Square Nut into the slot on the back of the x-motor holder using electronics pliers

-

The x-motor mount is now fully assembled.

-

-

-

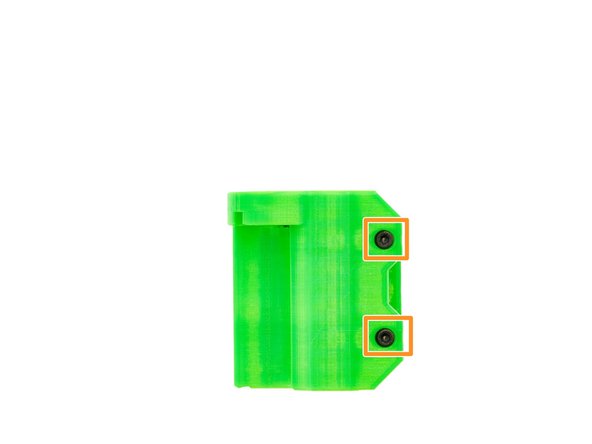

Insert 2x M3 Self Securing Nutsinto the back of the x-idler.

-

Insert 2x M3 Self-Securing Nutsinto the two slots on the top and bottom of the x-idler and lightly tightened them with 2x M3x16mm Hexagon Socket Head Cap Screws.

-

Push one of the greased LMUW10 bushings into the x-idler and ensure that it is centered.

-

Fasten it with 2x M3x30mm Hexagon Socket Head Cap Screws .

-

Make sure that you tighten the Hexagon Socket Head Cap Screws only minimally, as they should fit flush with the M3 Self-Securing Nuts.

-

-

-

Check the hole for the POM nut for filament protrusions and remove them with a knife or scalpel if necessary.

-

Insert 2x M3 Self-Securing Nutsinto the designated slots.

-

Insertion can be made easier with the help of an engineer scriber.

-

Now, put a POM Nut into the hole on the top.

-

Take 2x M3 Washers and 2x M3x14mm Hexagon Socket Head Cap Screws to fix the POM nut.

-

Make sure that you screw the screws into the two threaded holes of the POM nut.

-

Do not tighten the 2x M3x14mm Hexagon Socket Head Cap Screws completely for the time being.

-

The x-idler is now fully assembled.

-

-

-

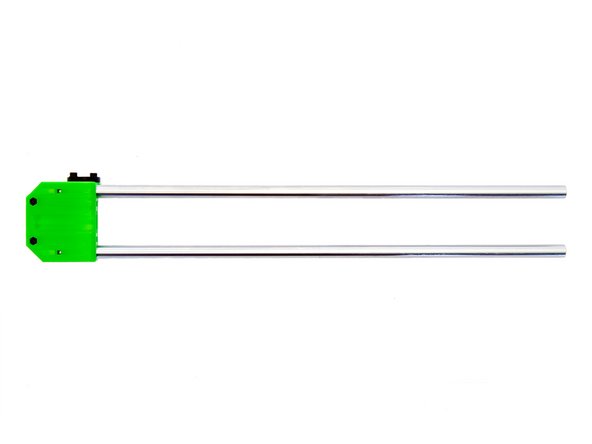

Place one of the 380mm x-Rods into one of the designated holes. Carefully tap the rod into the x-idler with a soft-faced hammer.

-

Repeat this step with the second rod.

-

Make sure the rods are pushed in all the way down by looking through the small window on the back of the x-idler.

-

-

-

Align the x-axis as shown in the first picture. Slide an LMUW10 bushing onto the upper x-rod and an LMU10 bushing onto the lower x-rod.

-

Remember to grease the bushings with Super Lube beforehand.

-

Align both x-rods with the holes in the x-idler and gently tap the x-idler with a soft-faced hammer.

-

The x-Idler has a small window on the back that allows you to check whether the rods are properly positioned.

-

-

-

The assembly of the x-axis is completed now.

-

Continue with instructions 13. Installation and Wiring of the x-Axis.

-

Cancel: I did not complete this guide.

One other person completed this guide.