-

-

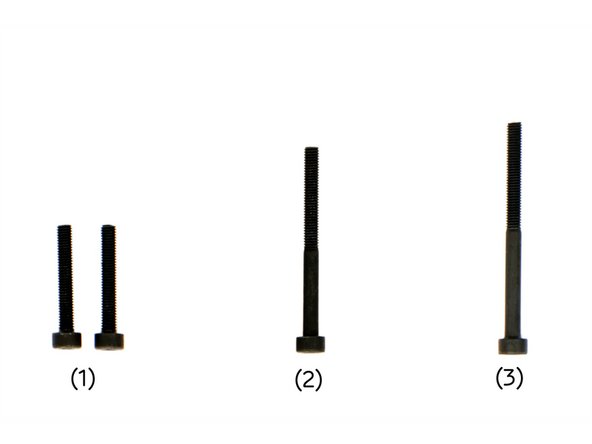

(1) 1.5x60mm Hexagon Socket Head Screwdriver for Electronic Applications

-

-

-

(4) Scalpel

-

-

(6) Pliers Wrench

-

(7) Engineer Scriber

-

(8) Countersink

-

-

-

-

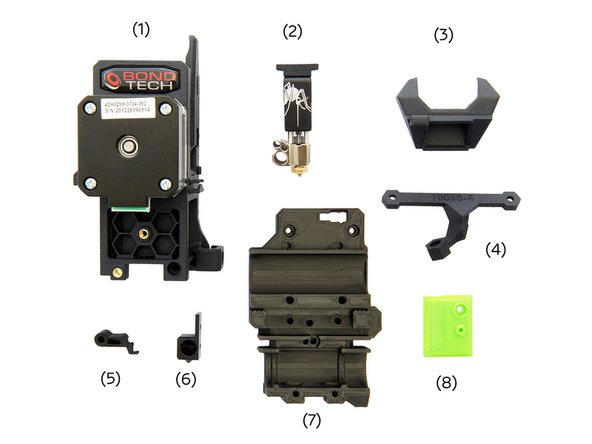

(2) Slice Engineering Hotend Mosquito/ Mosquito Magnum (see manual 14.1.)

-

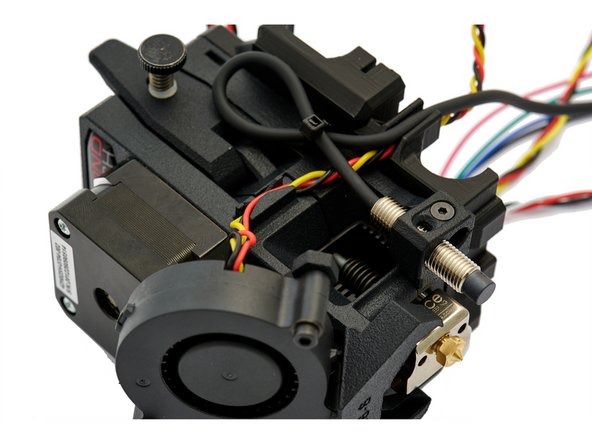

(3) Fan Shroud (Lüfterauslass)

-

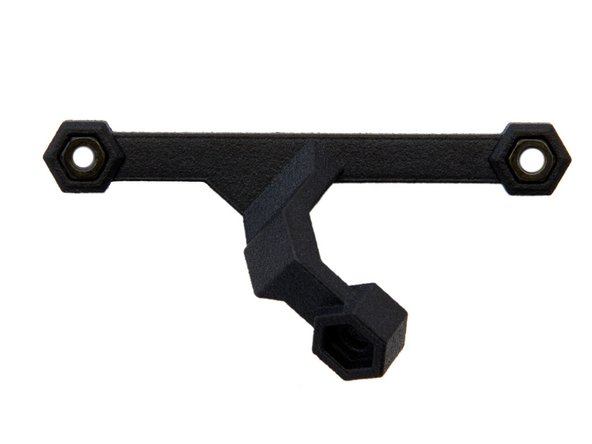

(4) Fan Holder

-

(5) Lever

-

(6) Ball Holder

-

(7) x-Carriage

-

(8) Sensor Cover

-

-

-

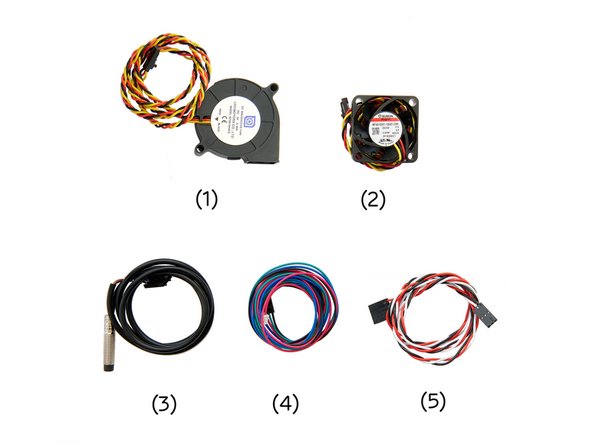

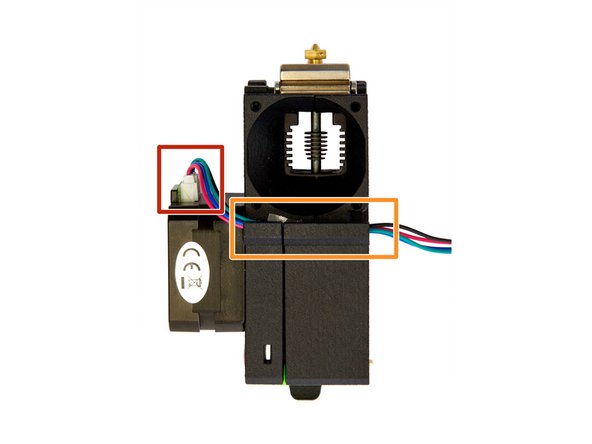

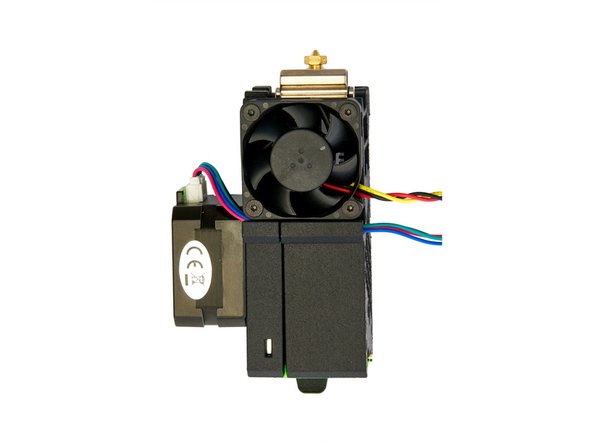

(1) Radial Fan

-

(2) Sunon Fan

-

(3) SuperPINDA /Pinda 2

-

-

(5) Motor Cable

-

-

-

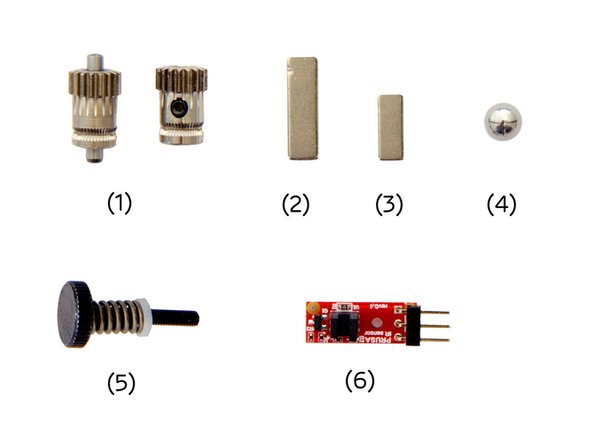

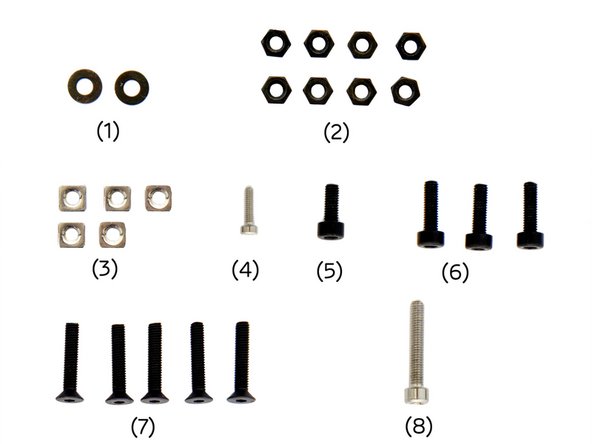

(1) 2x Black Washers

-

(2) 8x M3 Nuts

-

(3) 5x M3 Square Nuts

-

-

-

-

-

-

-

-

Open the extruder.

-

Insert the small magnet into the lever.

-

If the magnet is loose, fix it with a little super glue. If the magnet is difficult to insert, we recommend using a pliers wrench.

-

Place the lever in the extruder back (the one without motor) and secure it with a M3x18mm Hexagon Socket Head Cap Screw (silver).

-

Now, loosen the screw until the lever can be moved freely.

-

-

-

Insert the long magnet into the slot to the left of the lever.

-

Make sure that the two magnets repel each other.

-

If the magnet is still movable in the slot, fix it with super glue.

-

You can now test the mobility of the lever through the opening for the filament.

-

-

-

Take the ball holder and check the hole for filament residues. If there are any residues, remove them carefully (e.g. with a scalpel).

-

Insert the 7mm steel ball into the holder.

-

Insert the holder with ball into the top of the extruder back.

-

-

-

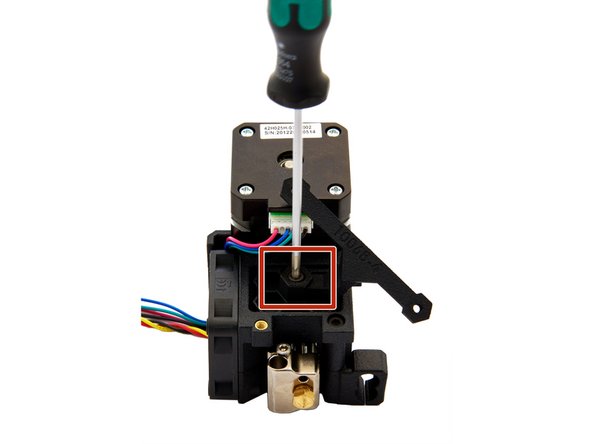

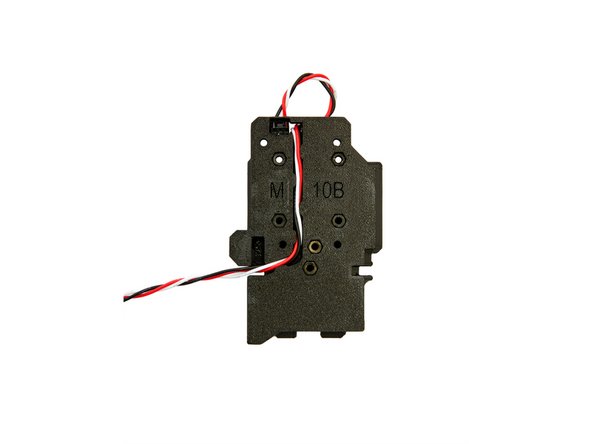

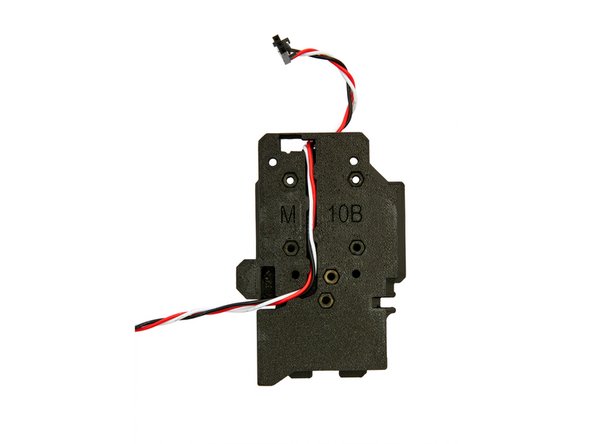

Insert the filament sensor and secure it with the M2x8mm Hexagon Socket Head Cap Screw (silver).

-

Test the mobility of the lever again.

-

If the lever's mobility is compromised, loosen the screw on the filament sensor minimally or check the lever for filament residue, removing it if necessary.

-

Test the mobility of the lever again.

-

Now, place the sensor cover on top and secure it with a M3x10mm Hexagon Socket Head Cap Screw.

-

-

-

Remove the hinge and shaft from the back of the extruder.

-

Align the gear (with the shaft) in the hinge as shown in Fig. 2 and press the shaft down until it engages.

-

Carefully press the shaft into position with a pliers wrench.

-

Re-assemble the hinge with the shaft to the back of the extruder.

-

-

-

Remove the shaft assembly from the front of the extruder.

-

Slide the gear onto the shaft and make sure that the M2 grub screw is aligned with the flat side of the shaft.

-

Tighten the screw so that the gear can only move up and down.

-

Insert the shaft assembly into the back of the extruder next to the hinge.

-

Make sure that there is a ball bearing (5x8x.2.5) in the cavity for the shaft.

-

Align the grooves in the gear to match the filament path and tighten the M2 grub screw.

-

-

-

Insert a M3 Square Nut into the hole, in the center of the extruder back. Make sure that the square nut is inside the left slot.

-

Remove shaft assembly from the back of the extruder and insert into the front of the extruder.

-

Make sure that there is a ball bearing (5x8x.2.5) in the cavity for the shaft.

-

-

-

Place your Mosquito/ Mosquito Magnum Hotend built in Manual 14.1. into the back of your extruder.

-

Make sure all components are seated properly before proceeding.

-

-

-

Now, put the front and back of the extruder together.

-

At the bottom of the front of the extruder, screw a M3x35mm Hexagon Socket Head Cap Screw through the extruder.

-

-

-

At the bottom of the front of the extruder, screw a M3x35mm Hexagon Socket Head Cap Screw through the extruder.

-

-

-

Install the Thumbscrew. Tighten the thumbscrew as much as possible and then loosen it again by 2-3 turns.

-

Insert a M3 Square Nut at the bottom of the back of the extruder.

-

Insert a M3 Square Nut into the top left corner of the back of the extruder.

-

-

-

On the Sunon Fan, enlarge the four screw holes with a countersink and remove the cable guide.

-

Plug the motor cable into the motor on the front of the extruder.

-

Push the motor cables into the cavity.

-

Place the Sunon Fan over it and be carefull to not damage the cables.

-

Pay attention to the orientation of the fan. The sticker on the fan must face inwards and the cable must come out to the rear.

-

Attach the Sunon Fan to the extruder using 4x M3x16mm Flat Head Screws.

-

-

-

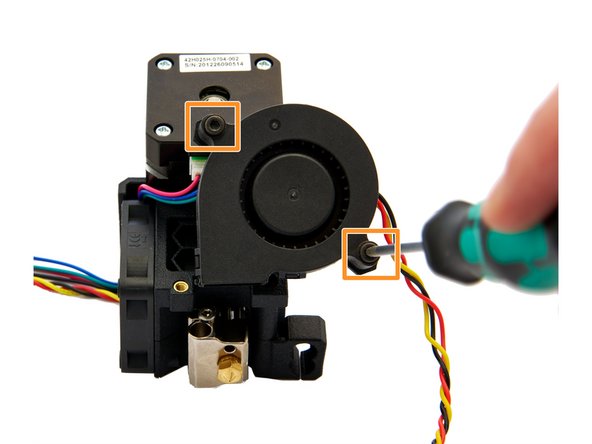

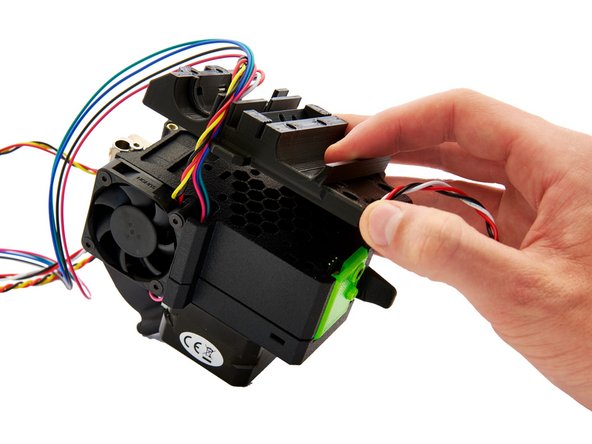

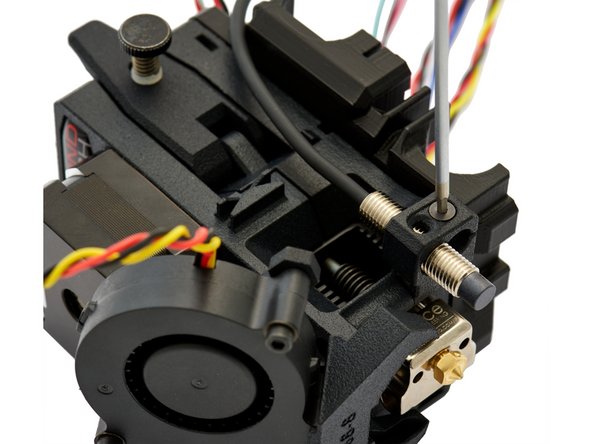

Insert 2x M3 Nuts into the fan holder.

-

Attach the fan holder to the extruder with a M3x10mm Hexagon Socket Head Cap Screw.

-

Carefully attach the Radial Fan to the extruder, using 2x Black Washers and 2x M3x20mm Hexagon Socket Head Cap Screws.

-

-

-

Insert 2x M3 Square Nuts into the bottom of the front of the x-carriage.

-

-

-

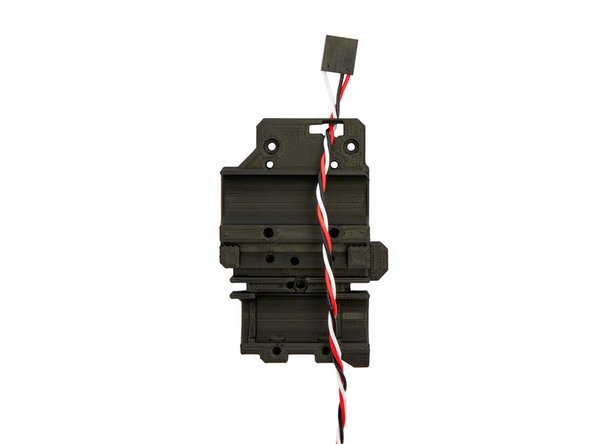

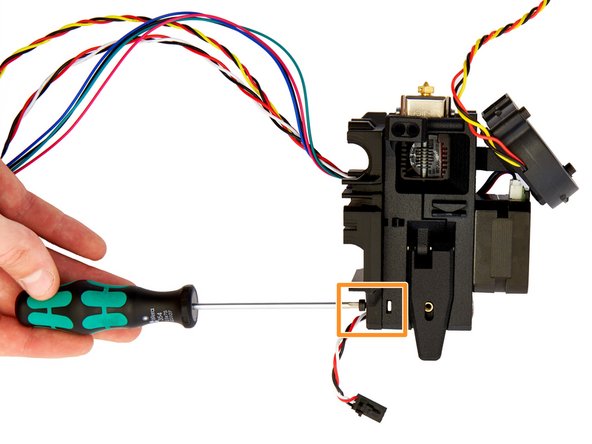

Feed the filament sensor cable connector through the top slot in the x-carriage (Fig. 1).

-

Pull the cable all the way through and insert the filament sensor cable connector (as shown in Figure 3) into the slot until it engages.

-

-

-

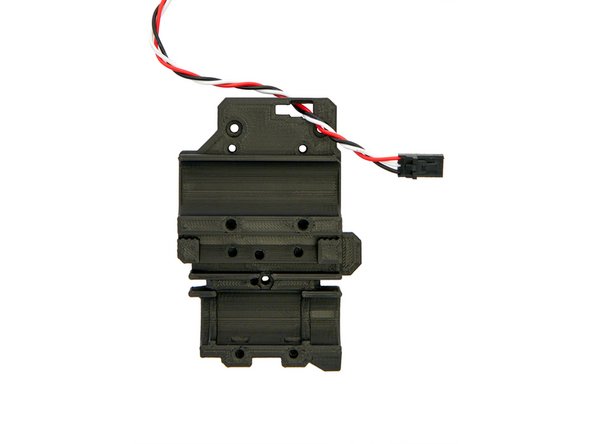

Now, feed the filament sensor cable through the cable guide in the back of the x-carriage.

-

Finally, remove the filament sensor cable connector from the x-carriage to avoid damaging the filament sensor during the installation of the x-carriage.

-

-

-

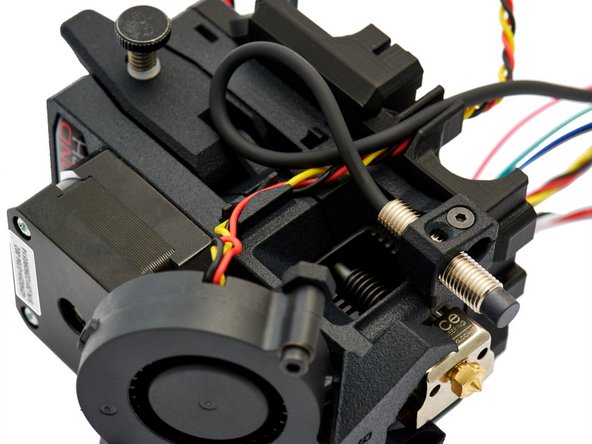

Place the x-carriage on the back of the extruder.

-

Be careful not to damage the filament sensor cable.

-

-

-

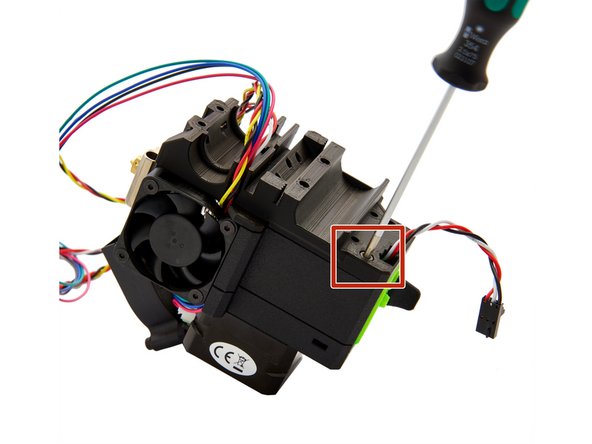

At the top right, the x-carriage is fastened with a M3x40mm Hexagon Socket Head Cap Screw.

-

At the top left, the x-carriage is fastened with a M3x10mm Hexagon Socket Head Cap Screw.

-

Plug the filament sensor cable onto the sensor.

-

Make sure that the plug snaps into place.

-

-

-

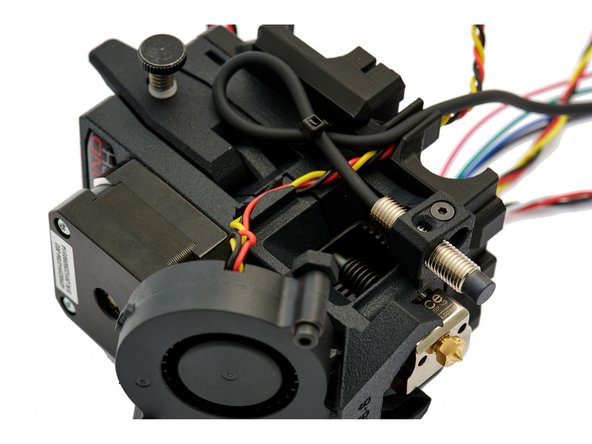

Insert the pinda into its mounts and fasten it with a M3x16mm Flat Head-Head Socket Cap Screw at the level of the nozzle.

-

Plug the cable of the radial fan into the mount provided on the right side of the extruder and guide it to the x-carriage.

-

Run the cable along the extruder (as shown in Fig. 3) and secure it with a zip tie.

-

-

-

The assembly of the Extruder is completed now.

-

Continue with instructions 16.1 Installation and Wiring of the Bondtech MK3S Mosquito Extruder.

-

Almost done!

Finish Line