-

-

(1) Heater Cartridge

-

(2) Thermistor Extension Cable

-

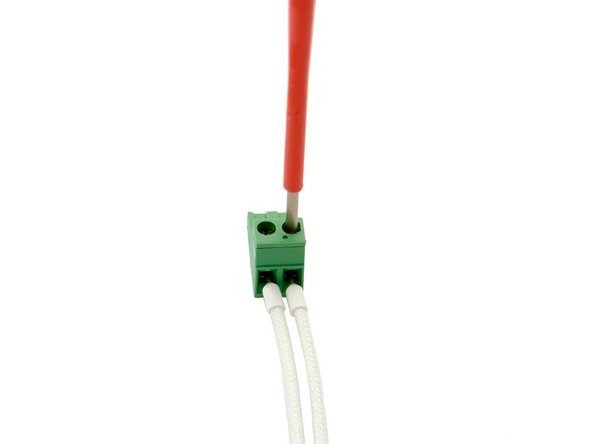

(3) Terminal Block

-

(4) Zip Ties

-

If you are building a Caribou 320 or 420 you will need the following extension cables:

-

-

(6) 2x Fan Extension Cable

-

(7) 2x Motor Extension Cable 20cm

-

-

-

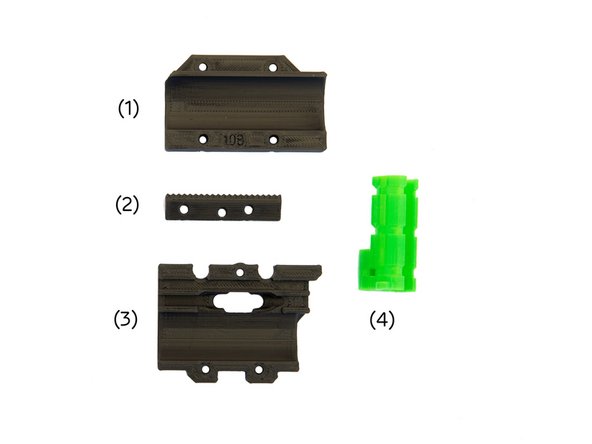

(1) x-Carriage Back (Top)

-

(2) Belt Holder

-

(3) x-Carriage Back (Bottom)

-

(4) x-Cable Holder

-

-

-

-

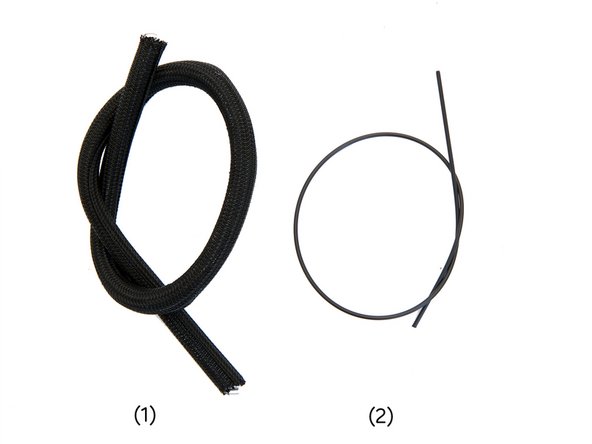

Caribou 220: 45cm

-

Caribou 320: 55cm

-

Caribou 420: 65cm

-

(2) Nylonfilament

-

Caribou 220: 47cm

-

Caribou 320: 57cm

-

Caribou 420: 67cm

-

-

-

-

-

-

-

-

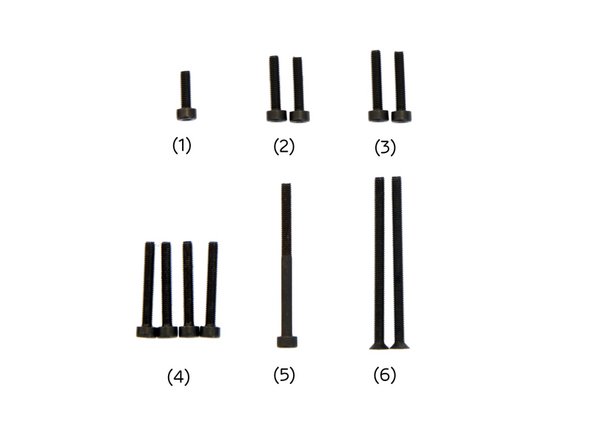

(6) 2x M3x45mm Hexagon Socket Head Cap Torx Screws

-

-

-

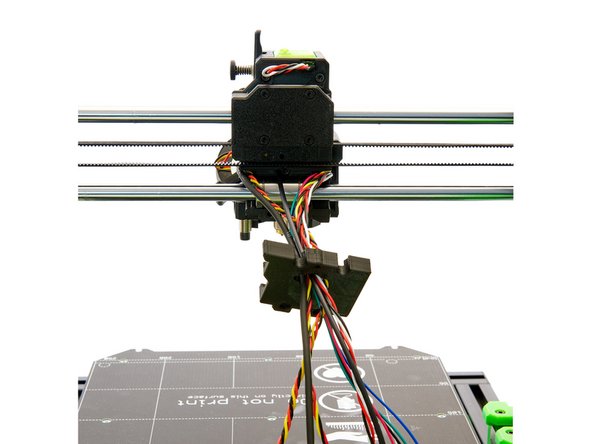

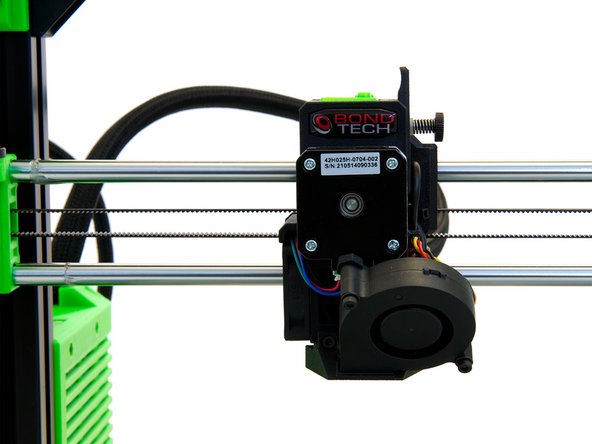

Turn your 3D printer around.

-

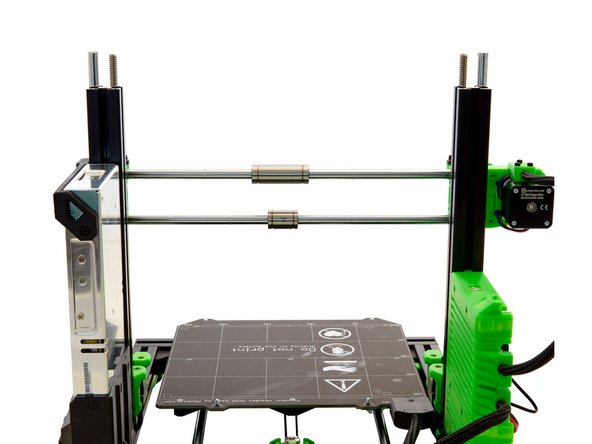

Move the x-axis to the upper third of the z-axis and push the two bushings on the x-axis to its center.

-

Check whether the two square nuts are located in the lower part (insertion for the lower bushing) of the x-carriage.

-

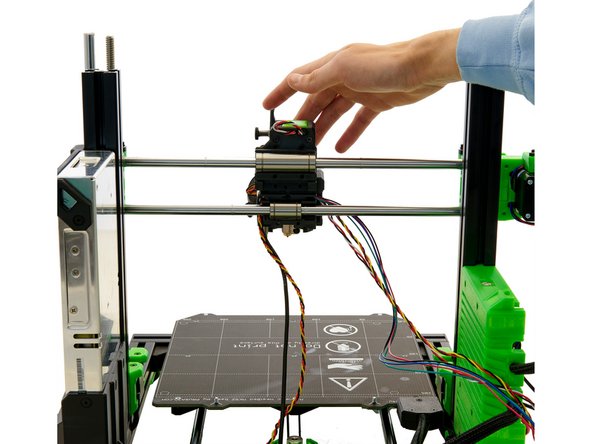

Hold the extruder against the bushings and make sure they are positioned in their designated openings.

-

Cover the upper bushing with the back of the x-carriage. Then, fasten the x-carriage back to the extruder with 4x M3x22mm Hexagon Socket Head Cap Screws.

-

-

-

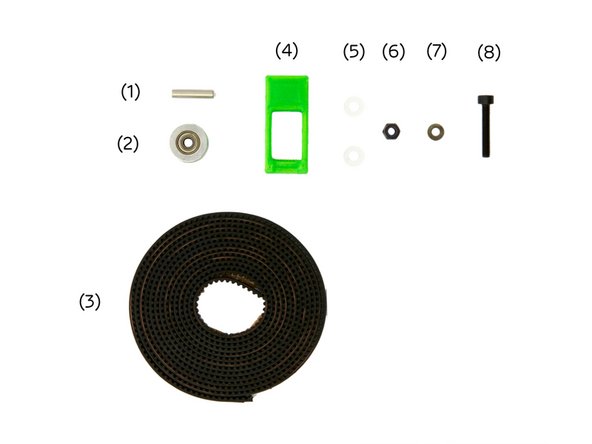

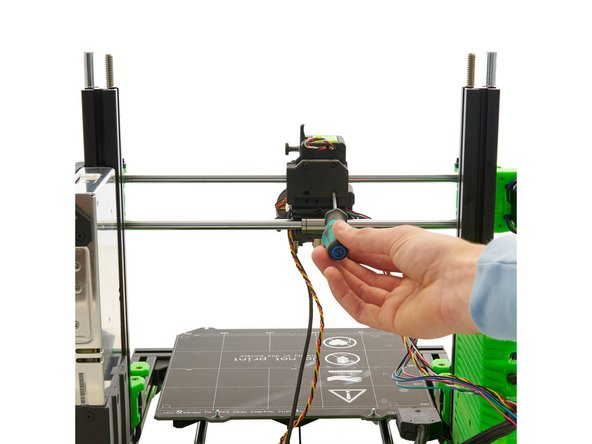

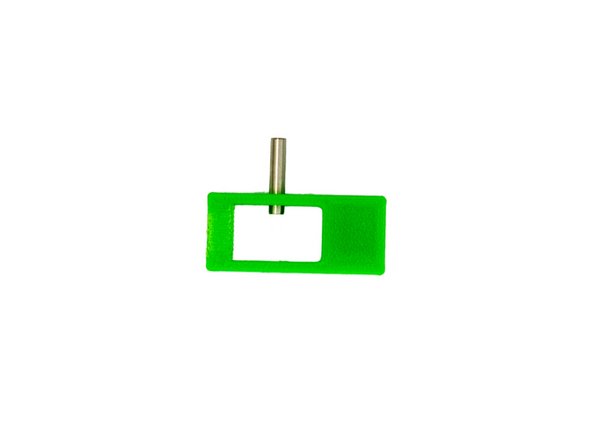

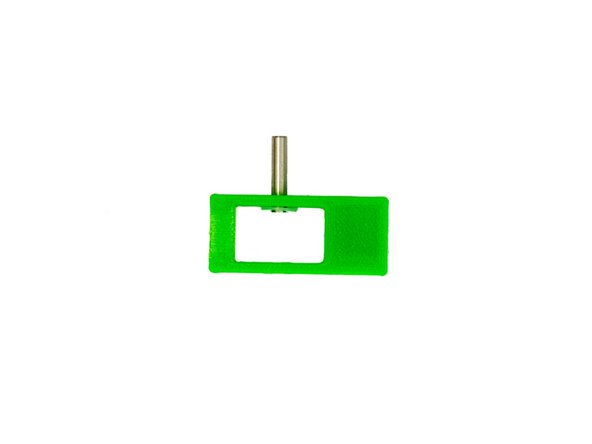

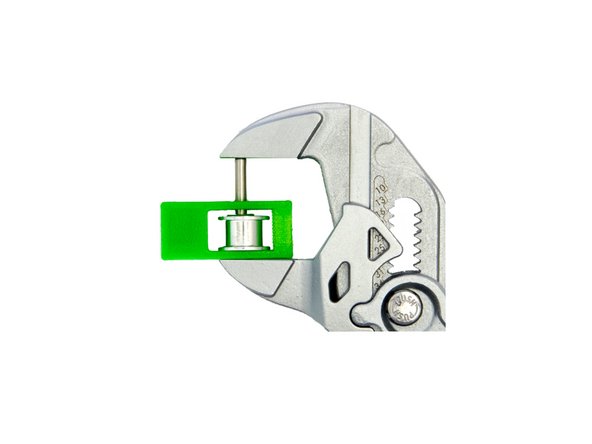

Take the xy-belt tensioner insert and enlarge one of the two holes on its side (e.g. with a 2.5x75mm hexagonal screwdriver).

-

Slide a dowel pin through the hole you just enlarged and push it in until it is just visible inside the xy-belt tensioner insert.

-

Place a M3 Plastic Washer on the dowel pin. (Fig. 2).

-

-

-

Now place a toothless pulley on the dowel pin. Continue to push the pin down until it reaches the end of the toothless pulley (Fig. 1).

-

Place a M3 Plastic Washer on the toothless pulley and, with the pliers wrench, push the dowel pin as far as possible through the opening of the xy-belt tensioner insert (Fig. 2)

-

Finally, place an M3 Self-Securing Nut into the designated slot. Press the nut completely into the slot.

-

Pay attention to the orientation. The blue circlip must point towards the pulley.

-

The xy-belt tensioner insert is now fully assembled.

-

Since you will need a second xy-belt tensioner insert for the x-axis, you can build another one in this step.

-

-

-

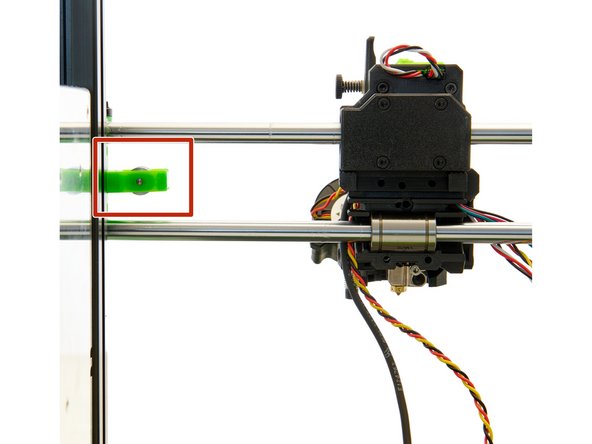

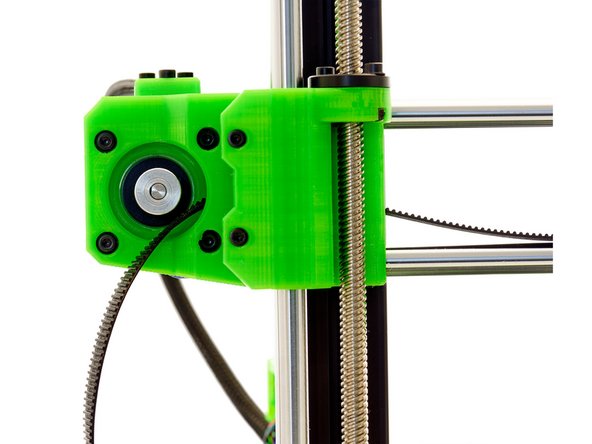

Insert the xy-belt tensioner insert into the idler.

-

Take the second half of the GT3 belt and shorten it to the length of 82 cm.

-

Cut the remaining GT3 belt to the length of 82cm.

-

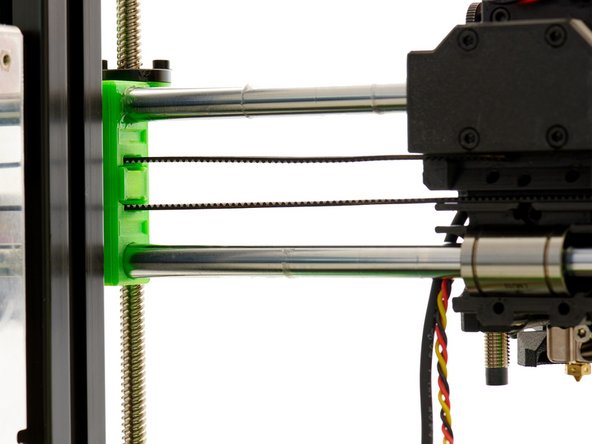

Pull the belt through the xy-belt tensioner insert (Fig. 2).

-

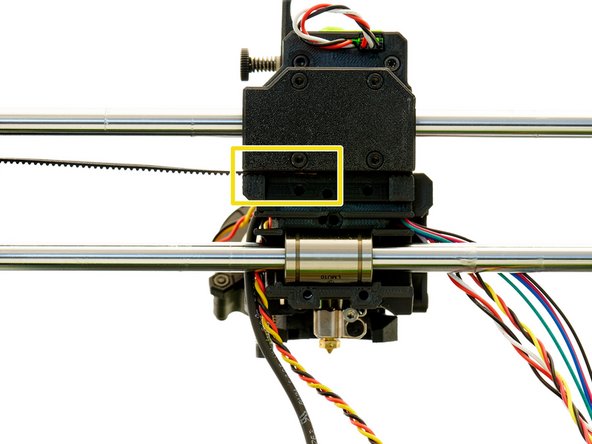

Push the end of the belt to approximately the center of the mount provided for it in the x-carriage.

-

-

-

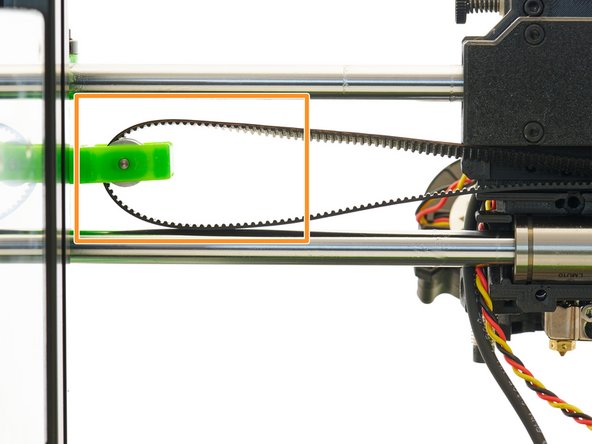

Place the GT3 belt around the GT3 toothed pulley on the stepper motor at the x-motor holder.

-

Slide the xy-belt tensioner insert into the y-Idler.

-

Secure the xy-belt tensioner insert with an M3 Washer and an M3x18mm Hexagon Socket Head Cap Screw.

-

Make sure the strap holder is flush with the idler for this step.

-

-

-

Now, guide the belt back to the x-carriage. If the two belt ends are overlapping in the middle, cut the protruding end.

-

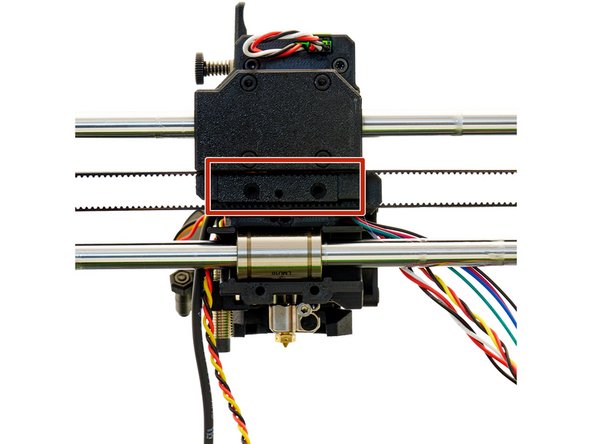

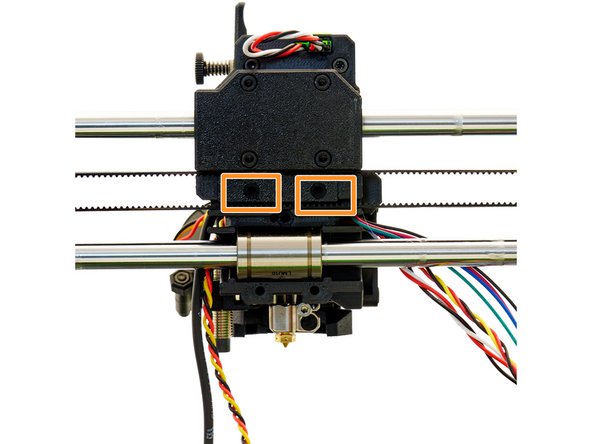

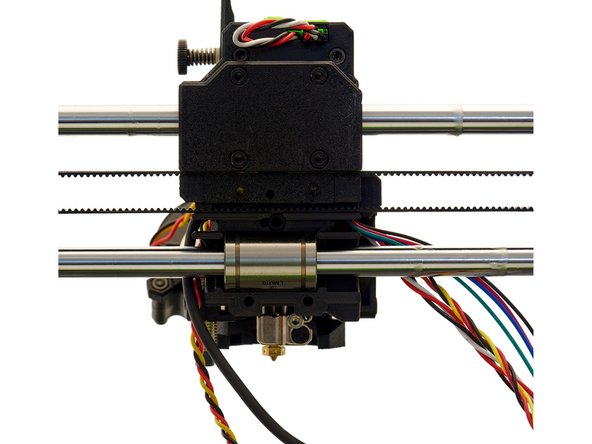

Place the belt holder in the x-carriage.

-

Fasten the belt holder with 2x M3x45mm FlatHead Screws.

-

-

-

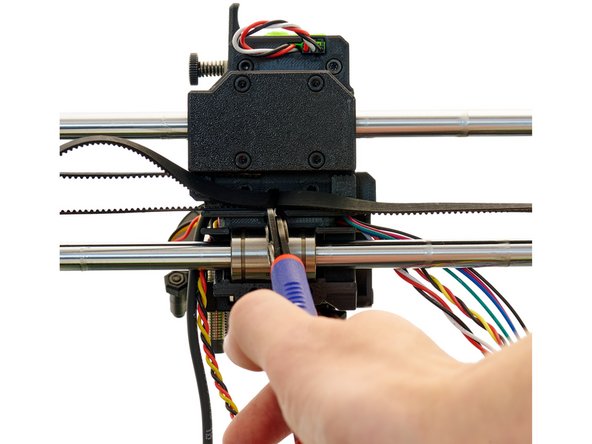

Cut your nylon filament so that the length fits your printer model (see Step 5).

-

Now, cut a slanted edge from one of the ends to make it pointed.

-

-

-

Insert the pointed end of the nylon filament into the left hole in the center of the x-carriage.

-

Use a M3x10mm Hexagon Socket Head Cap Screw in the right hole in the center of the x-carriage to attach the nylon filament.

-

-

-

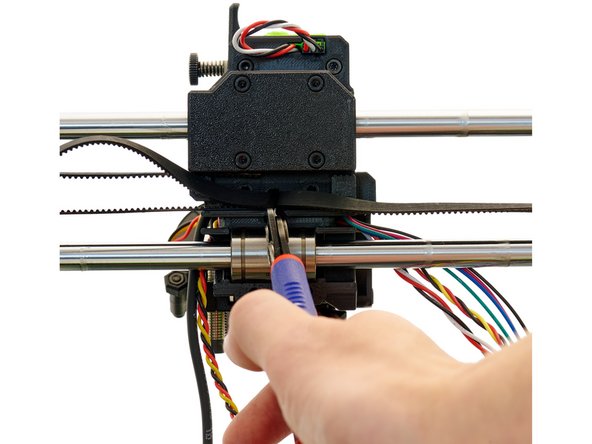

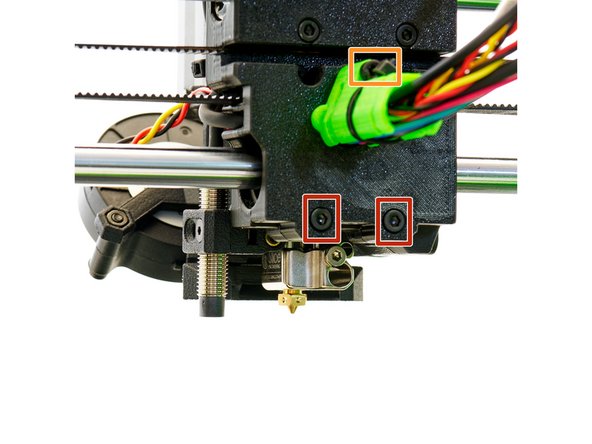

After that, pass the pinda cable, the filament sensor cable, the motor cable, the two fan cables and finally the nylon through the hole in the center of the x-carriage back (bottom).

-

Attach the x-carriage back (bottom) using 2x M3x16mm Hexagon Socket Head Cap Screws.

-

Fasten the x-cable holder to the extruder with a M3x40mm Hexagon Socket Head Cap Screw.

-

-

-

Loosen the M2x5mm Hexagon Socket Head Cap Screwon the Slice Engineering Hotend.

-

Open the boron nitride paste and apply it to the heater cartridge and the thermistor cartridge.

-

Insert the heater cartridge into the lower opening and the thermistor into the upper opening in the hotend. Secure both with a (previously removed) M2x5mm Hexagon Socket Head Cap Screw.

-

-

-

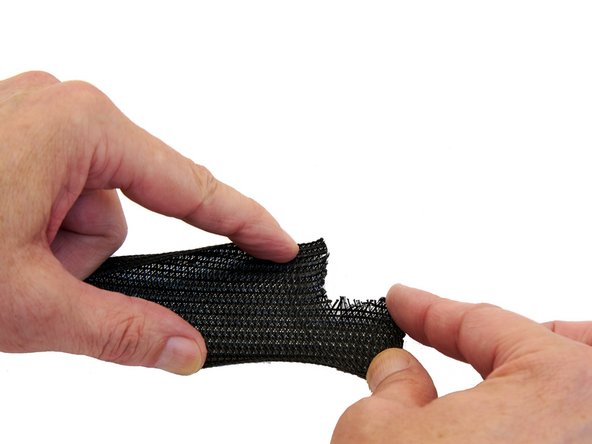

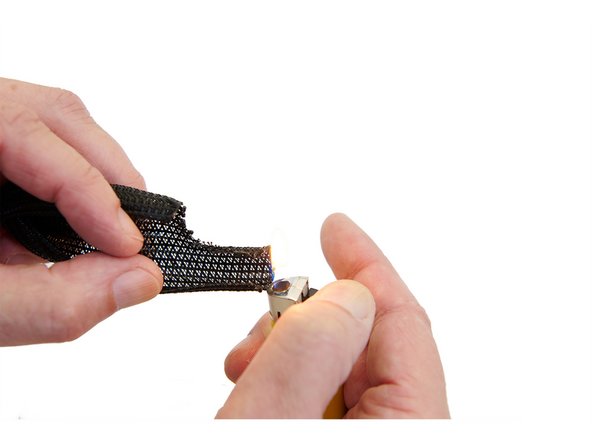

Cut Techflex tube and nylon to fit your printer model (see Step 5).

-

Cut an approximately 3x2cm rectangle from on one side of the Techflex tube (about 5cm before the end of the tube).

-

-

-

The two ends of the Techflex tube are then briefly heated with a lighter.

-

-

-

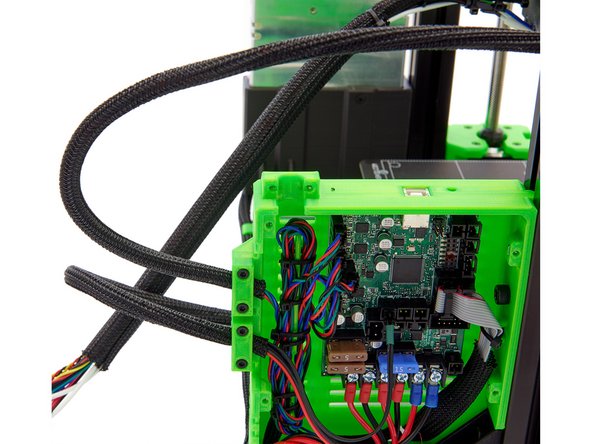

Push all the cables and the nylon filament through the Techflex tube you just prepared. Here, the end of the tube with the cut-out rectangle must be directed at the extruder.

-

Slide the Techflex tube completely into the x-cable holder and align the rectangle with the bottom to position the heater cartridge and thermistor cartridge cables there.

-

-

-

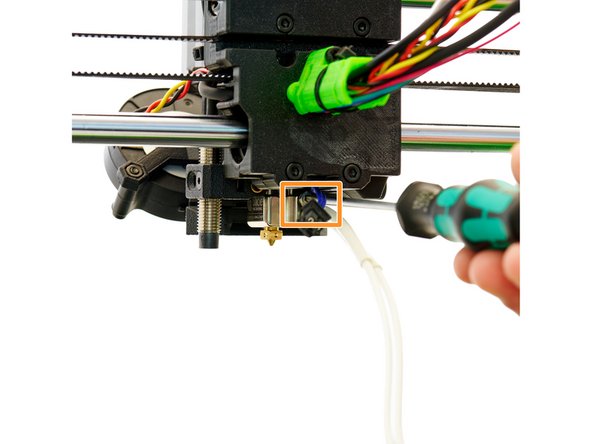

Now, route the heater cable and thethermistor cable through the rectangle and into the Techflex tube.

-

Secure the cables in the x-cable holder with 3x Zip Ties.

-

-

-

If you are building a Caribou 320 or Caribou 420, you will need to extend the pinda cable and extruder motor cable with a motor extension cable, the filament sensor cable with a filament sensor extension cable, and both fan cables with a fan extension cable.

-

Attach the Techflex tube to the Einsy box using the cable holder (straight) and 2x M3x14mmm Hexagon Socket Head Cap Screws.

-

-

-

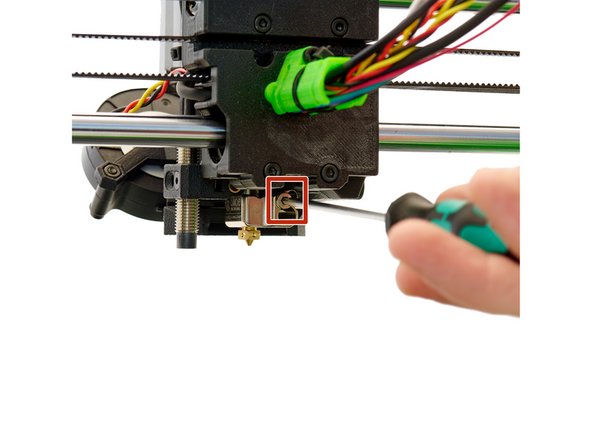

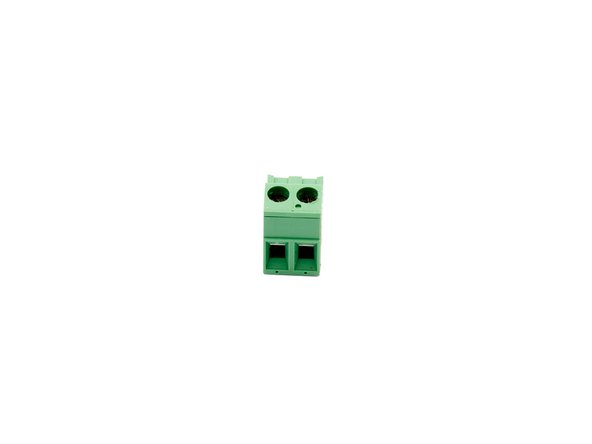

Use a screwdriver for slotted screws to loosen the two screws on the terminal block.

-

Push each of the two cable ends of the thermistor cartridge into one opening and secure them.

-

-

-

Now, connect the components to the board:

-

Heater cartridge

-

PINDA2 / SuperPINDA

-

Filament sensor (lower row of pins at the tub connector, white cable to the left)

-

-

-

Thermistor

-

Extruder-Fan (left), Radial-Fan (right)

-

Extruder-Motor

-

The extruder is now completely wired.

-

-

-

The installation of the extruder is completed now.

-

Continue with instructions 17. Installation of the Upper x-Profile.

-

Cancel: I did not complete this guide.

One other person completed this guide.