-

-

(1) Computer

-

(2) PSU cable

-

(3) USB cable

-

(4) Zip Ties

-

(5) Silicone Sock (only required if the E3D Hotend is installed)

-

(6) Foil Squeegee with Alcantara Cover (only required for BuildTak)

-

(7) Isopropanol

-

-

-

-

-

-

(4) Torque Wrench 1,5Nm (only required if a vanadium nozzle is installed)

-

Alternatively, a 6mm Cross-Handle Socket Wrench can be used.

-

(5) Pliers Wrench (only required for E3D Hotend)

-

Alternatively, you can use a...

-

(6) 16mm Open-End Wrench

-

-

-

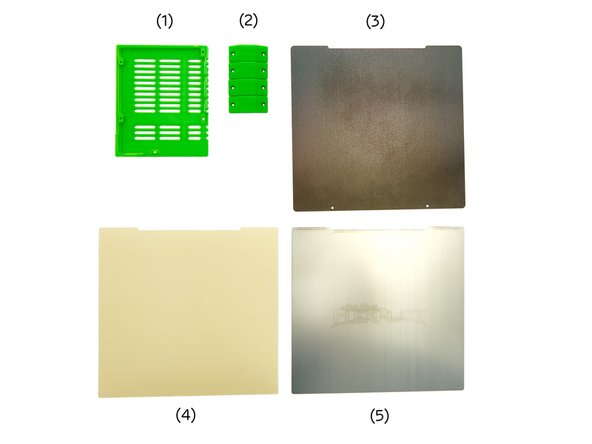

(1) Einsy Box Cover

-

(2) 4x Rod Holder Cover

-

Printing Surface

-

-

or

-

-

and

-

-

-

-

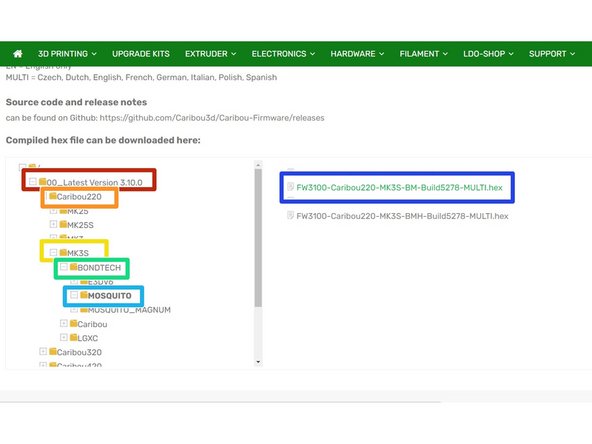

Visit Caribou3d.com to select the matching firmware for your printer model:

-

In the file manager, first select the folder "01_LatestVersion x.x.x".

-

Now, select your printer model and download the appropriate firmware. In our example we select a German firmware for a Caribou 220 MK3S with a Bondtech Mosquito and an SL Thermistor.

-

Printer height

-

Printer model

-

Extruder

-

Hotend

-

Finally, you have to choose a language ("EN" or "MULTI") and a thermistor version ("BM" or "BMH").

-

-

-

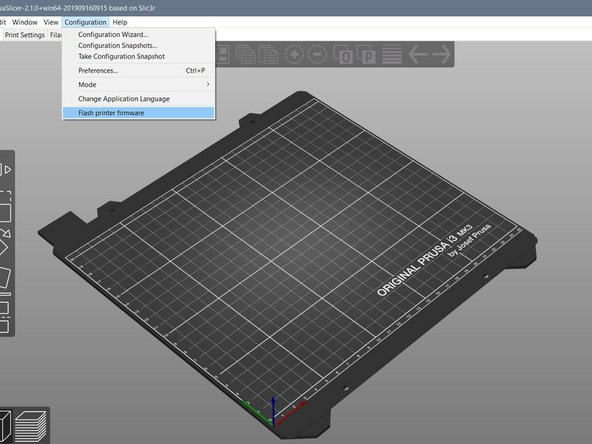

Download the program "Prusa Slicer" to your computer and install it on your PC / laptop.

-

Connect the power cable to the printer and turn it on.

-

The display should show the words "Caribou Research and Development" and the two fans should be activated.

-

Connect your printer to your computer using the supplied USB cable.

-

-

-

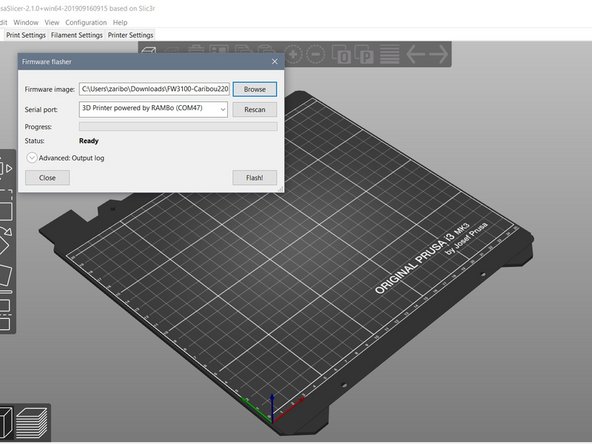

Open Prusa Slicer.

-

Select the following buttons in the top bar:

-

Configuration

-

Flash Printer Firmware

-

For Serial Port select "3D Printer powered by RAMBo".

-

At Firmware image select the firmware you downloaded.

-

Lastly, select "Flash".

-

This process may take a few minutes.

-

-

-

In the first step, the firmware is written.

-

In the second step, it is verified.

-

Do not interrupt this process! Damage to the Einsy board may occur.

-

-

-

Once the firmware upgrade is complete, you can select your preferred language for multi-language firmware.

-

Turn the knob on the display to switch between entries and press once to select individual entries.

-

Press the lower button to restart your printer.

-

You will then be asked if you want to use the "Wizard". Select "no" here.

-

-

-

You will then be asked if you want to use the "Wizard".

-

Select "no" here.

-

A message to restart the wizard will be displayed.

-

After pressing the knurled knob again, the selection menu is displayed.

-

-

-

After pressing the knob again, you will see the start screen.

-

Press and hold the knurled knob for 2-3 seconds. The display should now show "Z: +0.2".

-

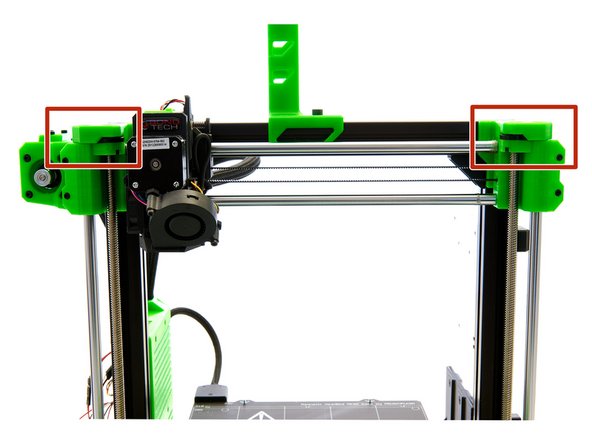

Turn the knurled know clockwise. This will cause the x-axis to move upwards.

-

Move the x-axis all the way up against the top mounts to make sure the x-axis is parallel to the bed.

-

This will produce a loud noise, which is normal.

-

Check whether both sides are touching the top mounts. If this is not the case, check to see why there is a blockage.

-

By turning the knob counterclockwise, you now move the axis down 3-4cm.

-

Press the knurled knob once to display the start screen.

-

-

-

Before proceeding, make sure the pinda is level with or slightly lower than the nozzle.

-

Press the knob again to go to the main menu.

-

There you select the following buttons:

-

Calibration

-

Autohome

-

The printer now moves each of the three axes to neutral position and then moves to the first reference point on the heatbed.

-

The start position is on the front left of the heatbed.

-

If the printer moves to a rear left position, you probably mounted the beltholder and the y-slide in the wrong direction and have to rotate it.

-

-

-

Press the knob again to go to the main selection.

-

There you select the following buttons:

-

Calibration

-

Selftest

-

Before proceeding, make sure the pinda is level with or slightly lower than the nozzle.

-

-

-

The firmware first verifies that both fans are spinning and connected properly.

-

After the first fan is checked and running, you will be asked whether the extruder fan (fan on the left side) is spinning. Check this and answer accordingly.

-

Now you are asked whether the part cooling fan (fan at the front) is spinning. Check this and answer accordingly.

-

If the test shows that the fan connections on the Einsy board have been reversed, switch off the printer and replace them. Then run the self-test again. If the test shows that the fan connections on the Einsy board have been reversed, switch off the printer and replace them. Then run the self-test again.

-

-

-

The firmware now checks whether the length of the three axes is correct.

-

First, the length of the x-axis and the y-axis is measured.

-

If an error message appears, check if there are cables sticking out from the sides of the extruder which are blocking the axis. For the y-axis, check the installation of the bearing holders and the installation of the belt holder or pulley.

-

If the SuperPINDA / PINDA does not activate properly, check the cables.

-

The start position is then calibrated.

-

The last part of the self-test is to check the heating of the heatbed and extruder.

-

If an error occurs here, check the wiring.

-

This completes the self-test successfully.

-

-

-

Select the following buttons in the main menu under Settings:

-

Temperature

-

Nozzle

-

Set the temperature to 250°C. Press the control knob twice to return to the start screen.

-

On the start screen you can monitor the temperature rise.

-

-

-

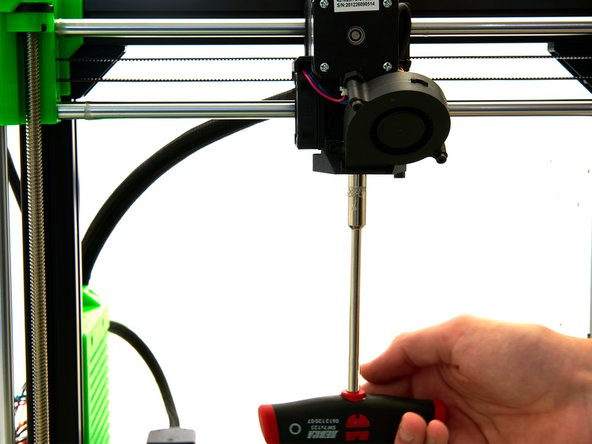

If you have installed a Mosquito Hotend, tighten the nozzle carefully with a t-handle socket wrench.

-

If you have installed a Mosquito Hotend with a Vanadium Nozzle, tighten the nozzle with a torque wrench.

-

If you have installed an E3D Hotend, hold the heater block with a 16mm open-end wrench and carefully tighten the nozzle with a t-handle socket wrench.

-

Make sure that the heating block is aligned straight.

-

-

-

Select the following buttons in the main selection under Settings:

-

Preheat

-

Cooldown

-

Wait until the temperature has dropped below 50°C.

-

If you have installed an E3D Hotend , you can insert the silicone sock.

-

Make sure that it is not sitting above the cables, but below them.

-

-

-

Move the x-axis all the way down and turn off the printer.

-

Turn the two spindles of the z-stepper motors simultaneously and evenly downward until the nozzle touches the bed.

-

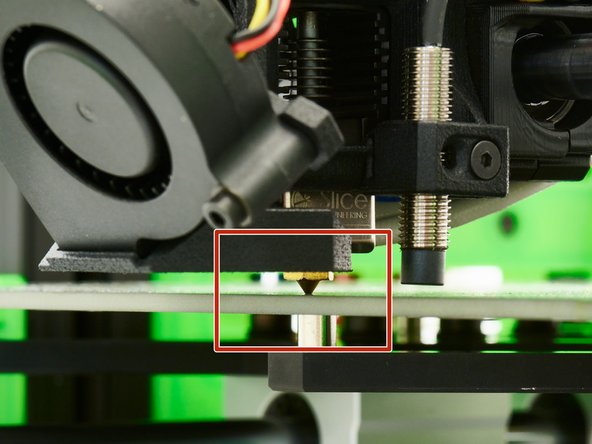

Loosen the M3x16mm Flat Head-Head Socket Cap Screw that holds the pinda in place.

-

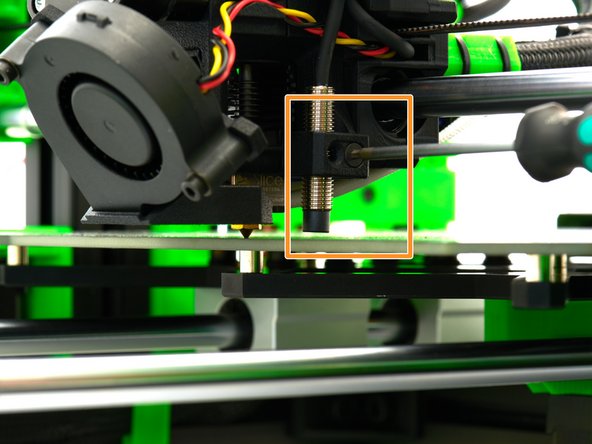

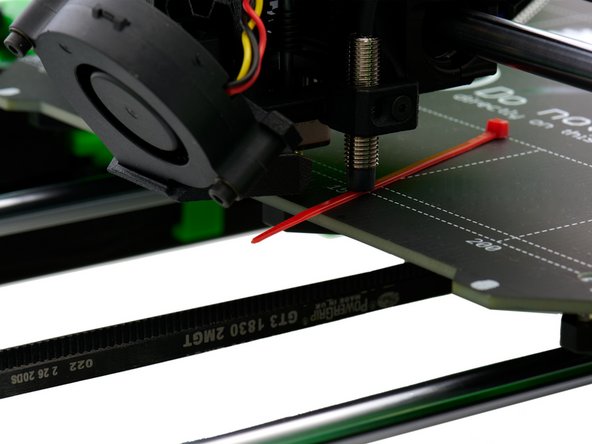

For illustration purposes, the zip tie in Fig. 3 is colored red.

-

Slide a zip tie beneath the PINDA and re-tighten the M3x16mm Flat Head-Head Socket Cap Screw.

-

The distance between the PINDA and the bed is now approximately 0.6mm. For a SuperPINDA, take a credit card or something similar. The distance should be about 1mm.

-

Turn the printer back on and realign the x-axis (see Step 11).

-

-

-

Press the knurled knob again to get to the main selection.

-

There, select the following buttons:

-

Calibration

-

Belt Test

-

Now the tension of the x- and y-belts is measured. The value should be between 225 and 250. A smaller value means higher tension.

-

If necessary, adjust the tension of the belts by loosening or tightening the set screw on the front belt holder and on the side of the middle screw on the x-Idler. After a readjustment, you must repeat the test.

-

-

-

You can check the current value of the belt tension as follows:

-

Press the knurled knob again to get to the main selection.

-

There, select the following buttons:

-

Support

-

Belt Status

-

Only the value of the last measurement is displayed. If an adjustment has been made, the belt test must be performed again.

-

-

-

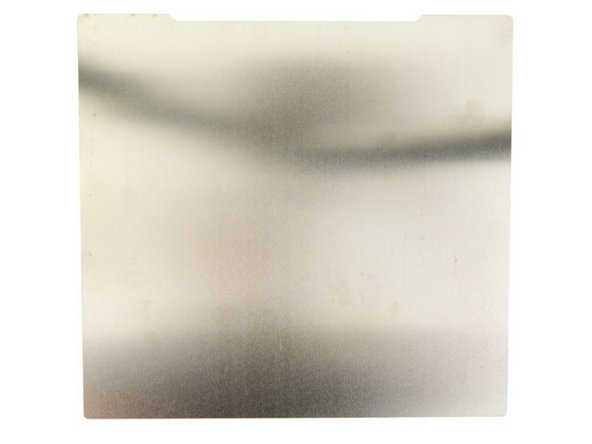

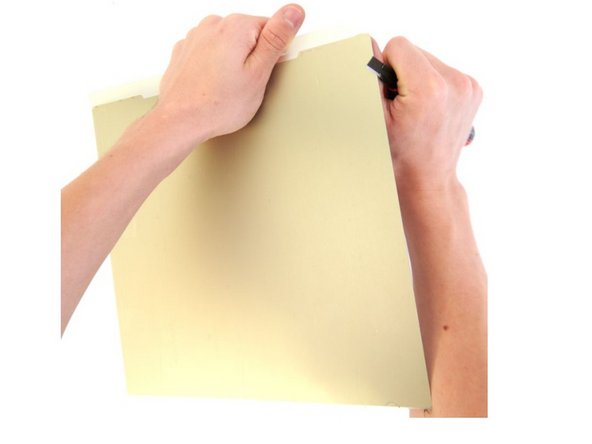

Remove the sticker from the BuildTak steel sheet and clean the sheet with isopropanol.

-

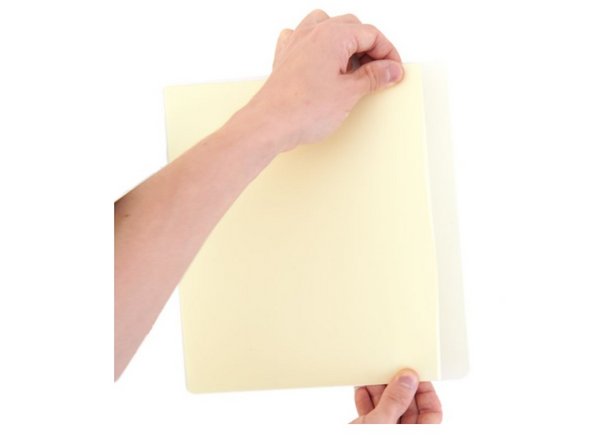

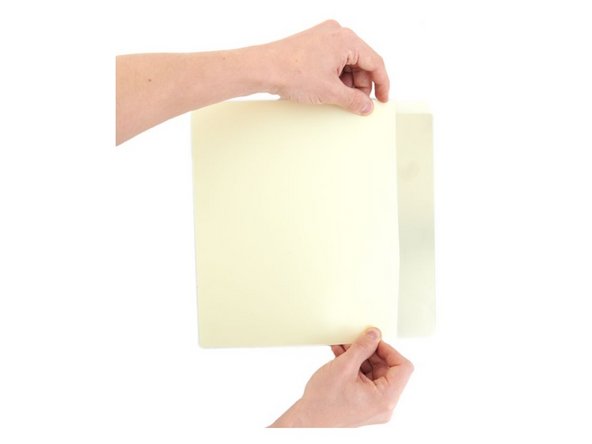

Remove the protective foil from the MK52 PEI Sheet by approx. 2-3cm.

-

Stick the MK52 PEI on the BuildTak Sheet side without logo.

-

Align the MK52 PEI Sheet on the BuildTak steel sheet (see Figure 3).

-

-

-

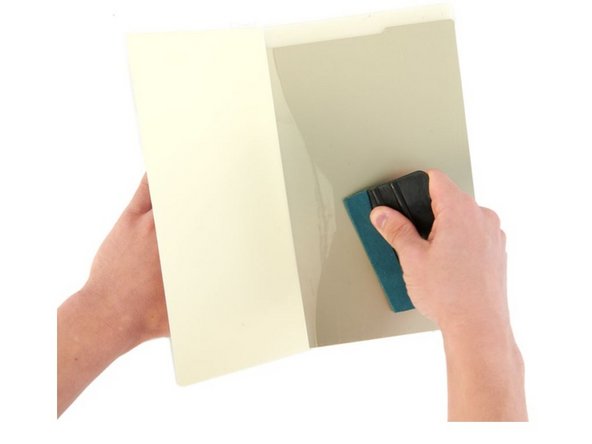

Now use the foil squeegee (or a spatula with a microfiber cloth) to apply the MK52 PEI Sheet to the Flexible Steel Sheet.

-

Remove the protective film piece by piece and squeegee the MK52 PEI Sheet to the Flexible Steel Sheet.

-

Always work in the direction of the not yet adhered MK52 PEI Sheet or towards the outer edges of the sheet.

-

Be especially careful around the edges. Only squeegee outwards. Otherwise, there is a risk that you will lift the MK52 PEI Sheet.

-

If necessary, remove the protruding parts of the MK52 PEI Sheet carefully with e.g. a knife.

-

Finally, clean the surface with isopropanol.

-

-

-

Select the following buttons in the main selection:

-

Calibration

-

Calibration XYZ

-

Make sure that there is no printing sheet on the heating bed. If the printer asks you about this, select "No".

-

Be careful that the Nozzle does not scratch the heatbed while the printer is measuring the 4 dots in the heated bed.

-

After measuring, the x-axis is moved up slightly. Now place your printing sheet on the heatbed to continue with the calibration.

-

The printer then measures 9 points on the bed.

-

-

-

The position of the four calibration points is measured.

-

After measuring, the x-axis is moved up slightly. Now, place your printing sheet on the heatbed to proceed with the calibration.

-

Now, the height of nine points on the printing bed is measured.

-

As the last step, the result of the calibration is displayed.

-

If the bed is crooked or if there is a fault, check the installation of the heatbed and the carriage.

-

-

-

The details of the calibration can be viewed under the support menu.

-

Select the following buttons in the main selection:

-

Support

-

XYZ Cal. Details

-

The most important factor here is the skew (the smaller, the better). If the value is below 0.11°, the printer will not perform any adjustments.

-

-

-

Place the rodholder covers (top) on the rodholders (bottom).

-

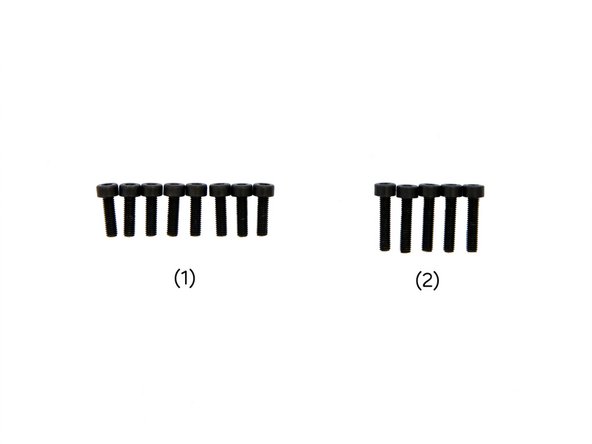

Now, tighten them with 2x M3x10mm Hexagon Socket Head Cap Screws.

-

Be careful not to overtighten the screws or the nuts underneath the rodholders may fall out.

-

-

-

Select the following buttons in the main selection under Settings:

-

Preheat

-

PLA

-

On the start screen you can monitor the temperature rise.

-

-

-

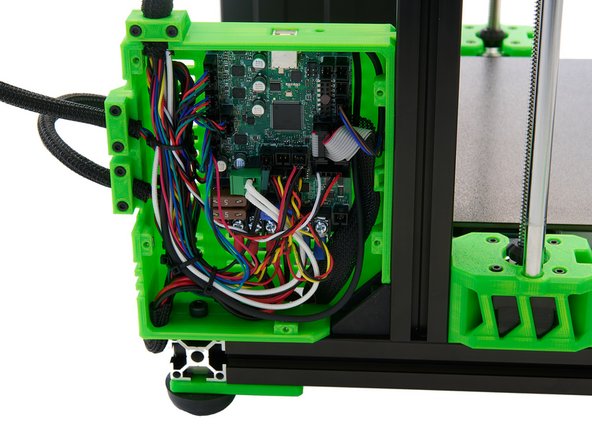

Place the cover on the Einsy Box.

-

Make sure that no cables are trapped between the cover and the box.

-

Now, fasten the cover with 5x M3x14mm Hexagon Socket Head Cap Screws.

-

Almost done!

Finish Line